Salvaged Materials 2.5 %

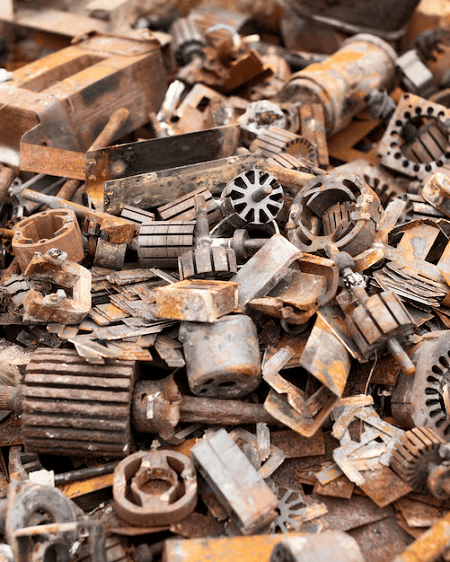

Salvaged Materials 2.5 % ? Salvaged materials can be a cost-effective and environmentally friendly option for a variety of projects. Here’s a breakdown of what you need to know: What are salvaged materials? Benefits of using salvaged materials: Things to consider when using salvaged materials: Where to find salvaged materials: Examples of salvaged materials in use: If you’re considering using salvaged materials, it’s essential to do your research and plan accordingly. By carefully selecting and preparing salvaged materials, you can create a beautiful and sustainable project. What is Salvaged Materials 2.5 % ? Salvaged materials are materials that have been reclaimed from existing structures or products that are no longer in use. They can include anything from wood and brick to metal, doors, windows, and even plumbing fixtures. Salvaged materials can be a cost-effective and environmentally friendly option for a variety of projects. They can add a unique and vintage look to your project, and they can also help to reduce the amount of waste that goes to landfills. If you’re considering using salvaged materials, it’s important to do your research and plan accordingly. By carefully selecting and preparing salvaged materials, you can create a beautiful and sustainable project. Who is required Salvaged Materials 2.5 % ? Unfortunately, there’s no universal “Salvaged Materials 2.5%” requirement that applies to everyone. Here’s why: To find out if any specific requirements apply to your situation, you’ll need to: Keep in mind that even without strict mandates, using salvaged materials can be beneficial for cost savings, environmental impact, and adding unique character to your project. When is required Salvaged Materials 2.5 % ? While there isn’t a universal “Salvaged Materials 2.5%” requirement, here’s when you might encounter specific regulations or incentives related to using salvaged materials: 1. Local Building Codes and Regulations: 2. Green Building Certifications: 3. Project-Specific Requirements: 4. Situational Considerations: Remember: COURTESY : The HISTORY® Channel Canada Where is required Salvaged Materials 2.5 % ? While there’s no universal “Salvaged Materials 2.5%” requirement, here’s where you might encounter specific regulations or incentives related to using salvaged materials: 1. Local Building Codes and Regulations: 2. Green Building Certifications: 3. Project-Specific Requirements: 4. Situational Considerations: Remember: How is required Salvaged Materials 2.5 % ? While there’s no universal mandate requiring a specific percentage of salvaged materials, here’s how the use of salvaged materials can be “required” or strongly encouraged: 1. Regulations and Codes: 2. Green Building Standards: 3. Project-Specific Needs: 4. Contractual Obligations: It’s important to remember: Even when not strictly “required,” using salvaged materials offers numerous benefits: By understanding the various ways salvaged materials can be “required,” you can make informed decisions about their use in your projects. Case study is Salvaged Materials 2.5 % ? While the concept of “Salvaged Materials 2.5%” might not be a common standard, it can be explored within the context of sustainable building practices and case studies. Here’s how: 1. Defining the Scope: 2. Identifying Opportunities: 3. Setting Targets: 4. Implementation: 5. Evaluation: Example Case Study: By examining specific case studies, we can understand how salvaged materials are used in practice, the challenges and benefits involved, and how to set realistic targets for their incorporation in future projects. COURTESY : Practical Engineering White paper on Salvaged Materials 2.5 % ? White Paper: Rethinking Construction – Exploring the Potential of Salvaged Materials (2.5% and Beyond) Abstract: The construction industry faces increasing pressure to adopt sustainable practices. This white paper challenges the conventional reliance on virgin materials and explores the potential of salvaged materials in achieving a more circular economy. While a fixed target like “2.5% salvaged materials” may not be universally applicable, this paper argues for a significant increase in the utilization of reclaimed resources, highlighting the benefits, challenges, and strategies for successful implementation. 1. Introduction: The demand for raw materials in construction is depleting natural resources and contributing significantly to environmental degradation. A shift towards a circular economy, where materials are reused and repurposed, is crucial. Salvaged materials, reclaimed from demolition or deconstruction projects, offer a viable alternative to virgin resources, reducing waste, lowering environmental impact, and often adding unique character to buildings. 2. The Case for Salvaged Materials: 3. Beyond the 2.5% Target: While a specific percentage like 2.5% can serve as a starting point for discussion, it shouldn’t be a limiting factor. The actual percentage of salvaged materials used should be determined by project-specific needs, material availability, and feasibility. A more holistic approach focusing on maximizing the use of reclaimed resources is necessary. 4. Challenges and Mitigation Strategies: 5. Strategies for Implementation: 6. Case Studies (Examples): 7. Conclusion: Moving beyond a fixed percentage target like 2.5%, this white paper advocates for a broader adoption of salvaged materials in the construction industry. By addressing the challenges and implementing the strategies outlined, we can unlock the full potential of reclaimed resources, creating a more sustainable and resilient built environment. Further research and development are needed to refine material processing techniques, establish standardized testing methods, and create a robust framework for integrating salvaged materials into mainstream construction practices. 8. Recommendations: This white paper provides a starting point for a broader conversation about the role of salvaged materials in sustainable construction. By embracing innovation and collaboration, we can create a future where buildings are not only structures but also repositories of valuable resources, contributing to a truly circular economy. Industrial application of Salvaged Materials 2.5 % ? You’re right to think about the industrial applications of salvaged materials! While the “2.5%” figure might not be a strict rule, the concept of reusing and repurposing materials is highly relevant in various industrial settings. Here’s how salvaged materials find their way into industrial applications: 1. Raw Material Substitution: 2. Manufacturing Processes: 3. Energy Production: 4. Other Industrial Uses: Examples of Industrial Applications: Benefits of Using Salvaged Materials in Industry: By incorporating salvaged materials into their processes, industries can contribute to a more sustainable and circular economy. Research and development of Salvaged Materials 2.5 % ? You’re hitting on a really