Ergonomics ?

Ergonomics, also known as human factors, is essentially the science of fitting workplaces, products, and systems to the people who use them. Here’s a breakdown:

- Core Idea:

- It’s about optimizing the interaction between humans and their environment.

- The goal is to enhance well-being and overall system performance.

- It focuses on “fitting the job to the person,” rather than the other way around.

- Key Aspects:

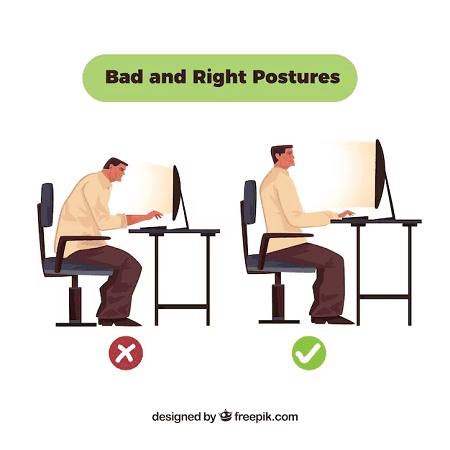

- Physical Ergonomics: This deals with physical activity, posture, material handling, and repetitive movements. It aims to reduce musculoskeletal disorders (MSDs).

- Cognitive Ergonomics: This focuses on mental processes, such as perception, memory, reasoning, and motor response, as they affect interactions among humans and other elements of a system.

- Organizational Ergonomics: This is concerned with the optimization of sociotechnical systems, including their organizational structures, policies, and processes.

- Why it’s important:

- Reduces injuries: It helps prevent work-related injuries like back pain, carpal tunnel syndrome, and other MSDs.

- Increases productivity: When people are comfortable and their environment is optimized, they can work more efficiently.

- Improves comfort and well-being: Ergonomics contributes to a more comfortable and healthy work environment.

In essence, ergonomics seeks to create a safer, more efficient, and more comfortable experience for people in their interactions with technology and their surroundings.

What is Ergonomics ?

Ergonomics, also known as human factors, is a scientific discipline that focuses on understanding the interactions between humans and other elements of a system. Essentially, it’s about:

- Fitting the work to the worker:

- Rather than forcing people to adapt to their work environment, ergonomics aims to design or modify that environment to suit human capabilities and limitations.

- Optimizing well-being and performance:

- The goal is to improve people’s comfort, health, safety, and efficiency in their interactions with products, systems, and environments.

Here are some key aspects of ergonomics:

- Physical ergonomics:

- Deals with physical aspects of work, such as posture, movement, and material handling.

- Cognitive ergonomics:

- Focuses on mental processes, such as perception, memory, and decision-making.

- Organizational ergonomics:

- Addresses the optimization of organizational structures, policies, and processes.

In simpler terms, ergonomics is about creating a better fit between people and their surroundings, whether it’s in the workplace, at home, or anywhere else.

Who is required Ergonomics ?

Essentially, everyone can benefit from ergonomics, but it’s particularly crucial for those who:

- Perform repetitive tasks:

- This includes people who work on computers, assembly lines, or any job that involves repetitive motions.

- Work in physically demanding jobs:

- Construction workers, healthcare professionals, and anyone who lifts heavy objects or works in awkward postures.

- Spend long periods sitting or standing:

- Office workers, drivers, and retail employees are at risk for musculoskeletal disorders.

- Use tools or equipment:

- Properly designed tools can prevent injuries and improve efficiency.

Here’s a broader perspective:

- Employers:

- Implementing ergonomic practices can reduce workplace injuries, increase productivity, and lower costs associated with workers’ compensation.

- Employees:

- Ergonomics helps prevent pain, discomfort, and long-term health problems.

- Consumers:

- Ergonomically designed products, from furniture to electronics, enhance comfort and usability in everyday life.

In summary, while some professions have a higher risk of ergonomic-related issues, the principles of ergonomics are applicable to anyone who interacts with their environment.

When is required Ergonomics ?

Ergonomics is not a “sometimes” thing; it’s a “always” thing. However, there are definitely times when it becomes especially critical. Here’s a breakdown:

Key Times Ergonomics Is Essential:

- During Workplace Design:

- When setting up new workstations, offices, or factories.

- When introducing new equipment or technology.

- This is the ideal time to “build in” ergonomic principles.

- When Repetitive Tasks Are Performed:

- Any job that involves repeated motions (typing, assembly line work, etc.) requires careful ergonomic consideration.

- This helps prevent repetitive strain injuries.

- When Physical Strain Is Involved:

- Jobs with heavy lifting, awkward postures, or prolonged standing/sitting.

- Construction, healthcare, and warehousing are prime examples.

- When Experiencing Discomfort or Pain:

- If you start feeling pain, numbness, or tingling, it’s a clear sign that ergonomic adjustments are needed.

- Don’t wait for serious injuries to develop.

- When Using Computers and Technology:

- Prolonged computer use can lead to various problems, so proper workstation setup is crucial.

- This includes monitor placement, keyboard and mouse positioning, and chair adjustments.

- Proactively:

- The best time for ergonomics is before problems arise. Proactive ergonomic assessments and adjustments can prevent injuries and increase productivity.

In essence:

- Ergonomics is always relevant, but it’s particularly vital when tasks or environments pose a risk to physical or cognitive well-being.

By understanding these points, you can recognize when ergonomic principles should be applied to create a safer and more comfortable environment.

COURTESY : Altec Incorporated

Where is required Ergonomics ?

Ergonomics is applicable in a wide range of environments, essentially anywhere humans interact with their surroundings. Here are some key areas where ergonomics is crucial:

- Workplaces:

- Offices: Computer workstations, seating, lighting, and overall office layout.

- Factories and industrial settings: Assembly lines, material handling, tool design, and heavy machinery operation.

- Construction sites: Use of tools, heavy lifting, and working in various weather conditions.

- Healthcare facilities: Patient handling, medical equipment design, and long hours on feet.

- Transportation: Truck driving, aviation, and other transportation industries where prolonged sitting or repetitive actions are common.

- Homes:

- Home offices: Ensuring proper computer setup and comfortable seating.

- Kitchens: Optimizing counter heights and appliance placement.

- Living areas: Furniture design and layout for comfort and support.

- Public Spaces:

- Schools: Classroom furniture and computer labs.

- Retail stores: Checkout counters and product display.

- Public transportation: Seat design and accessibility.

- Product Design:

- Consumer electronics: Designing devices that are comfortable and easy to use.

- Tools and equipment: Ensuring that tools are designed to minimize strain and prevent injuries.

- Furniture: Creating chairs, desks, and other furniture that provide proper support.

Essentially, any environment or product that involves human interaction can benefit from ergonomic considerations. The goal is to create a better, safer, and more efficient experience for people in all aspects of their lives.

How is required Ergonomics ?

Implementing ergonomics effectively involves a systematic approach that addresses various aspects of the work environment and individual needs. Here’s a breakdown of how ergonomics is typically implemented:

1. Assessment and Analysis:

- Identify Risk Factors:

- This involves observing work tasks, analyzing job requirements, and identifying potential hazards that could lead to musculoskeletal disorders (MSDs) or other ergonomic issues.

- Factors to consider include repetitive motions, awkward postures, excessive force, and prolonged static positions.

- Data Collection:

- Gather information through surveys, interviews, and direct observation of workers.

- Analyze injury records and employee feedback to identify problem areas.

2. Implementing Solutions:

- Engineering Controls:

- Modify the work environment to reduce or eliminate hazards.

- Examples:

- Adjustable workstations and chairs.

- Ergonomic tools and equipment.

- Redesigning work processes.

- Administrative Controls:

- Implement changes to work practices and policies.

- Examples:

- Job rotation.

- Scheduled breaks and stretching exercises.

- Training on proper lifting techniques.

- Training and Education:

- Educate employees on ergonomic principles and safe work practices.

- Provide training on how to properly use ergonomic equipment and adjust workstations.

- Encourage employees to report any discomfort or pain.

3. Evaluation and Monitoring:

- Regular Assessments:

- Continuously monitor the effectiveness of ergonomic interventions.

- Conduct regular assessments to identify any new or emerging hazards.

- Feedback and Adjustments:

- Gather feedback from employees and make necessary adjustments to ergonomic solutions.

- Track injury rates and other relevant metrics to evaluate the success of the program.

Key Considerations:

- Employee Involvement:

- Involve employees in the ergonomic process to ensure that solutions are practical and effective.

- Management Support:

- Gain support from management to provide the necessary resources and commitment to ergonomics.

- Continuous Improvement:

- Ergonomics is an ongoing process that requires continuous improvement and adaptation.

By following these steps, organizations can create a safer and more comfortable work environment that promotes employee well-being and productivity.

Case study is Ergonomics ?

Yes, case studies are very important in the field of ergonomics. They provide real-world examples of how ergonomic principles are applied, and they demonstrate the impact that ergonomic interventions can have. Here’s why case studies are so relevant to ergonomics:

- Practical Application:

- Ergonomics is a science that is meant to be applied. Case studies show how theoretical concepts translate into practical solutions in various work environments.

- Demonstrating Effectiveness:

- Case studies often include data that shows how ergonomic changes have reduced injuries, increased productivity, or improved employee comfort. This provides concrete evidence of the benefits of ergonomics.

- Identifying Best Practices:

- By examining successful ergonomic interventions, case studies help to identify best practices that can be applied in other settings.

- Illustrating Diverse Applications:

- Ergonomics is relevant in a wide range of industries and settings. Case studies showcase the diversity of ergonomic applications, from office environments to industrial settings and healthcare facilities.

- Problem solving:

- Case studies are used to show how to address specific ergonomic problems. For example, a case study might detail how a company reduced repetitive strain injuries among its assembly line workers.

Here are some examples of what an ergonomics case study might involve:

- A study of how a company redesigned its office workstations to reduce musculoskeletal disorders among its employees.

- An analysis of how a hospital implemented ergonomic patient handling techniques to reduce back injuries among nurses.

- An examination of how a manufacturing plant redesigned its assembly line to improve efficiency and reduce worker fatigue.

Organizations like OSHA (Occupational Safety and Health Administration) and the Chartered Institute of Ergonomics & Human Factors provide access to many ergonomics case studies. These resources can be very valuable for anyone interested in learning more about ergonomics.

COURTESY : UCLA

White paper on Ergonomics ?

White papers on ergonomics serve as valuable resources for understanding and implementing ergonomic principles in various settings. They typically delve into specific ergonomic issues, provide in-depth analysis, and offer practical recommendations. Here’s a breakdown of what you can expect and where to find them:

Purpose of Ergonomics White Papers:

- In-depth Analysis:

- They provide detailed examinations of specific ergonomic challenges, such as workplace musculoskeletal disorders, cognitive load, or the impact of technology on human performance.

- Evidence-Based Recommendations:

- They often draw on scientific research and industry best practices to offer evidence-based solutions.

- Industry-Specific Guidance:

- Many white papers focus on specific industries, such as healthcare, manufacturing, or office environments, providing tailored recommendations.

- Promoting Awareness:

- They help raise awareness of the importance of ergonomics and its impact on health, safety, and productivity.

Where to Find Ergonomics White Papers:

- Human Factors and Ergonomics Society (HFES):

- The HFES is a leading professional organization in the field of ergonomics. Their website offers a collection of white papers covering various ergonomic topics.

- Here is a link to their white papers page: https://www.hfes.org/Publications/White-Papers

- Occupational Safety and Health Administration (OSHA):

- OSHA provides resources and publications related to workplace ergonomics, including guidelines and best practices.

- Industry-Specific Organizations:

- Many industry-specific organizations, such as those in healthcare or manufacturing, publish white papers on ergonomics related to their respective fields.

- Ergonomics Solution Providers:

- Companies that provide ergonomic products and services often publish white papers to educate their customers and promote their solutions. For example, companies that create ergonomic office furniture.

- Academic and Research Institutions:

- Universities and research institutions conduct studies on ergonomics and may publish their findings in white papers.

Key Topics Covered in Ergonomics White Papers:

- Workplace Ergonomics:

- Office ergonomics, industrial ergonomics, and prevention of musculoskeletal disorders.

- Cognitive Ergonomics:

- Human-computer interaction, cognitive load, and decision-making.

- Healthcare Ergonomics:

- Patient handling, medical device design, and healthcare worker safety.

- Product Design Ergonomics:

- Designing products that are comfortable, safe, and easy to use.

When searching for white papers, it’s helpful to use specific keywords related to your area of interest, such as “office ergonomics,” “healthcare ergonomics,” or “cognitive ergonomics.”

Industrial application of Ergonomics ?

Industrial ergonomics focuses on optimizing the interaction between workers and their work environments in industrial settings. This is crucial for preventing injuries, improving productivity, and enhancing overall workplace safety. Here’s a breakdown of its key applications:

Key Industrial Applications:

- Manufacturing and Assembly:

- Designing workstations to minimize repetitive motions, awkward postures, and excessive force.

- Optimizing tool design and placement for efficient and safe use.

- Implementing material handling solutions to reduce lifting and carrying strain.

- Material Handling:

- Analyzing lifting and carrying tasks to identify and mitigate risks.

- Providing training on proper lifting techniques.

- Using mechanical aids, such as forklifts and hoists, to reduce manual handling.

- Construction:

- Addressing hazards related to heavy lifting, working at heights, and using power tools.

- Implementing ergonomic practices for tasks such as concrete work, framing, and roofing.

- Providing personal protective equipment (PPE) that fits properly and minimizes strain.

- Warehousing and Distribution:

- Optimizing warehouse layout and picking processes to reduce travel distances and lifting.

- Designing ergonomic packaging and labeling systems.

- Providing training on safe forklift operation and manual handling techniques.

- Agriculture:

- Addressing hazards related to repetitive tasks, exposure to weather, and use of machinery.

- Designing ergonomic farm equipment and tools.

- Implementing practices to reduce exposure to vibration and noise.

Core Ergonomic Principles in Industrial Settings:

- Reducing Repetitive Motion Injuries:

- By redesigning tasks and tools, ergonomics aims to minimize repetitive motions that can lead to carpal tunnel syndrome and other injuries.

- Minimizing Physical Strain:

- Ergonomics focuses on reducing the amount of force required to perform tasks, thus lessening the risk of muscle strains and back injuries.

- Improving Posture:

- Proper workstation design and tool placement help workers maintain neutral postures, reducing stress on joints and muscles.

- Enhancing Safety:

- By creating safer work environments, ergonomics helps to prevent accidents and injuries.

- Boosting Productivity:

- When workers are comfortable and safe, they are more productive and efficient.

In essence, industrial ergonomics is about creating a work environment that is tailored to the capabilities and limitations of the human body, resulting in a healthier, safer, and more productive workplace.

Research and development of Ergonomics ?

Research and development in ergonomics is a dynamic and evolving field, driven by the need to adapt to changing technologies, work environments, and societal needs. Here’s an overview of key aspects:

Key Areas of Research and Development:

- Advanced Biomechanics:

- Researchers are using advanced technologies like motion capture, electromyography (EMG), and force platforms to gain a deeper understanding of human movement and biomechanics.

- This helps in designing more effective interventions to prevent musculoskeletal disorders.

- Cognitive Ergonomics and Human-Computer Interaction (HCI):

- With the increasing prevalence of digital technologies, research is focused on optimizing human-computer interaction.

- This includes studies on cognitive load, user interface design, and the impact of artificial intelligence on human performance.

- Virtual and Augmented Reality (VR/AR):

- VR and AR technologies are being used for ergonomic assessments and training.

- Researchers are developing virtual environments to simulate work tasks and evaluate ergonomic risks.

- VR is also used to create immersive training programs that teach proper lifting techniques and other ergonomic principles.

- Wearable Technology and Sensors:

- Wearable sensors are being used to monitor worker posture, movement, and physiological responses in real-time.

- This data can be used to identify ergonomic risks and provide personalized feedback to workers.

- Ergonomics in Healthcare:

- Research is focused on improving patient handling techniques, designing ergonomic medical devices, and optimizing healthcare work environments.

- This aims to reduce injuries among healthcare workers and improve patient safety.

- Organizational Ergonomics:

- Researchers are studying the impact of organizational factors, such as work schedules, job design, and management practices, on worker health and well-being.

- This includes research on work-life balance, stress management, and the impact of remote work.

- Anthropometry and Inclusive Design:

- Ongoing research is conducted to gather up to date anthropometric data from diverse populations.

- This is to ensure that products and environments are designed to accommodate the needs of all users, including those with disabilities.

Driving Forces:

- Technological Advancements:

- The rapid pace of technological change is driving the need for ongoing ergonomic research.

- Aging Workforce:

- As the workforce ages, there is a growing need to address the ergonomic needs of older workers.

- Increased Awareness of Musculoskeletal Disorders:

- Increased awareness of the impact of work-related musculoskeletal disorders is driving demand for effective ergonomic interventions.

In summary, ergonomics research and development is a multifaceted field that plays a crucial role in creating safer, healthier, and more productive work environments.

COURTESY : MedStar Health

References

- ^ Wickens; Gordon; Liu (1997). An Introduction to Human Factors Engineering (PDF). Archived from the original (PDF) on 19 June 2018.

- ^ Jump up to:a b ISO 6385 defines “ergonomics” and the “study of human factors” similarly, as the “scientific discipline concerned with the understanding of interactions among humans and other elements of a system, and the profession that applies theory, principles and methods to design to optimize overall human performance.”

- ^ “What is ergonomics?”. Institute of Ergonomics and Human Factors. 9 September 2023. Archived from the original on 30 July 2021. Retrieved 4 April 2021.

Essentially yes, they are different terms with the same meaning but one term may be more in favour in one country or in one industry than another. They can be used interchangeably.

- ^ “CRIOP” (PDF). SINTEF.

Ergonomics is a scientific discipline that applies systematic methods and knowledge about people to evaluate and approve the interaction between individuals, technology and organisation. The aim is to create a working environment and the tools in them for maximum work efficiency and maximum worker health and safety … Human factors is a scientific discipline that applies systematic methods and knowledge about people to evaluate and improve the interaction between individuals, technology and organisations. The aim is to create a working environment (that to the largest extent possible) contributes to achieving healthy, effective and safe operations.

- ^ Jump up to:a b c d International Ergonomics Association. Human Factors/Ergonomics (HF/E). Website. Retrieved 7 June 2020.

- ^ “Safety and Health Topics | Ergonomics | Occupational Safety and Health Administration”. www.osha.gov. Retrieved 28 March 2019.

- ^ Grandjean, E. (1980) Fitting the Task to the Man: An Ergonomic Approach. Taylor & Francis; 3rd Edition.

- ^ “Wojciech Jastrzębowski”. Archived from the original on 24 November 2011. Retrieved 19 July 2012.

- ^ Hywel Murrell

- ^ Swain, A.D.; Guttmann, H.E. (1983). “Handbook of Human Reliability Analysis with Emphasis on Nuclear Power Plant Applications. NUREG/CR-1278” (PDF). USNRC.

Human Factors Engineering, Human Engineering, Human Factors, and Ergonomics … describe a discipline concerned with designing machines, operations, and work environments so that they match human capacities and limitations … The first three terms are used most widely in the United States … The last term, ergonomics, is used most frequently in other countries but is now becoming popular in the United States as well.

- ^ “Home Page of Environmental Ergonomics Society”. Environmental-ergonomics.org. Retrieved 6 April 2012.

- ^ John L. Campbell; Monica G. Lichty; et al. (2012). National Cooperative Highway Research Project Report 600: Human Factors Guidelines for Road Systems (Second ed.). Washington, D.C.: Transportation Research Board.

- ^ “Human Factors Engineering Professional Education University of Michigan”. nexus.engin.umich.edu. Retrieved 15 March 2021.

- ^ Madeleine, P., Vangsgaard, S., de Zee, M., Kristiansen, M. V., Verma, R., Kersting, U. G., Villumsen, M., & Samani, A. (2014). Ergonomics in sports and at work. In Proceedings, 11th International Symposium on Human Factors in Organisational Design and Management, ODAM, & 46th Annual Nordic Ergonomics Society Conference, NES, 17–20 August 2014, Copenhagen, Denmark (pp. 57–62). International Ergonomics Association.

- ^ “Ergonomic Guidelines for Common Job Functions Within The Telecommunication Industry” (PDF). Archived from the original (PDF) on 30 January 2023.

- ^ Kaplan, Sally. “6 affordable products that have helped me deal with back pain and muscle tension”. Insider. Retrieved 15 March 2021.

- ^ Walsh, Isabel A P.; Oishi, Jorge; Coury, Helenice J C Gil (2008). “Clinical and functional aspects of work-related musculoskeletal disorders among active workers”. Revista de Saúde Pública. 42 (1): 108–116. doi:10.1590/s0034-89102008000100014. PMID 18200347.

- ^ Charles N. Jeffress (27 October 2000). “BEACON Biodynamics and Ergonomics Symposium”. University of Connecticut, Farmington, Conn.

- ^ Jump up to:a b “Workplace Ergonomics: NIOSH Provides Steps to Minimize Musculoskeletal Disorders”. 2003. Archived from the original on 19 June 2008. Retrieved 23 April 2008.

- ^ Jeffress, Charles N. (27 October 2000). BEACON Biodynamics and Ergonomics Symposium. Farmington, Connecticut: University of Connecticut.

- ^ “Ergonomic Guidelines for Common Job Functions Within The Telecommunication Industry” (PDF).

- ^ “What Is Ergonomics and Its Application in The Real World”. spassway. Retrieved 15 March 2021.

- ^ Jump up to:a b c Neuhaus, M.; Eakin, E. G.; Straker, L.; Owen, N.; Dunstan, D. W.; Reid, N.; Healy, G. N. (October 2014). “Reducing occupational sedentary time: a systematic review and meta-analysis of evidence on activity-permissive workstations” (PDF). Obesity Reviews. 15 (10): 822–838. doi:10.1111/obr.12201. ISSN 1467-789X. PMID 25040784. S2CID 9092084.

- ^ Peternel, Luka; Fang, Cheng; Tsagarakis, Nikos; Ajoudani, Arash (2019). “A selective muscle fatigue management approach to ergonomic human–robot co-manipulation”. Robotics and Computer-Integrated Manufacturing. 58. Elsevier: 69–79. doi:10.1016/j.rcim.2019.01.013.

- ^ Kim, Wansoo; Peternel, Luka; Lorenzini, Marta; Babič, Jan; Ajoudani, Arash (2021). “A Human–Robot Collaboration Framework for Improving Ergonomics During Dexterous Operation of Power Tools”. Robotics and Computer-Integrated Manufacturing. 68. Elsevier: 102084. doi:10.1016/j.rcim.2020.102084. ISSN 0736-5845.

- ^ Peternel, Luka; Schøn, Daniel Tofte; Fang, Cheng (2021). “Binary and Hybrid Work-Condition Maps for Interactive Exploration of Ergonomic Human Arm Postures”. Frontiers in Neurorobotics. 14. Frontiers: 114. doi:10.3389/fnbot.2020.590241. PMC 7819876. PMID 33488376.

- ^ H. Diamantopoulos and W. Wang, “Accommodating and Assisting Human Partners in Human–Robot Collaborative Tasks through Emotion Understanding,” in 2021 International Conference on Mechanical and Aerospace Engineering (ICMAE), 2021: IEEE, pp. 523–528.

- ^ Huang, H. (2015). Development of New Methods to Support Systemic Incident Analysis (Doctoral dissertation, Queen Mary University of London).

- ^ Hollnagel, E. (2018). Safety–I and safety–II: the past and future of safety management. CRC press.

- ^ Dart, R. A. (1960). “The Bone Tool-Manufacturing Ability of Australopithecus Prometheus”. American Anthropologist. 62 (1): 134–138. doi:10.1525/aa.1960.62.1.02a00080.

- ^ Marmaras, N.; Poulakakis, G.; Papakostopoulos, V. (August 1999). “Ergonomic design in ancient Greece”. Applied Ergonomics. 30 (4): 361–368. doi:10.1016/S0003-6870(98)00050-7. PMID 10416849.

- ^ Franco, Giuliano; Franco, Francesca (2001). “Bernardino Ramazzini: The Father of Occupational Medicine”. American Journal of Public Health. 91 (9): 1382. doi:10.2105/AJPH.91.9.1382. PMC 1446786. PMID 11527763.

- ^ Jump up to:a b c d e Nikolayevich Myasishchev estia.com/library/1358216/the-history-of-human-factors-and-ergonomics The History of Human Factors and Ergonomics[permanent dead link], David Meister

- ^ Jump up to:a b Neville Moray (2005). Ergonomics: The history and scope of human factors. Routledge. ISBN 9780415322577. OCLC 54974550. OL 7491513M. 041532257X.

- ^ Porter, Elias H. (1964). Manpower Development: The System Training Concept. New York: Harper and Row, p. xiii.

- ^ “WHAT DOES HUMAN FACTORS MEAN?”. www.linkedin.com. Retrieved 14 November 2022.

- ^ “NASA-STD-3000”.

1.2 OVERVIEW.

- ^ “Association of Canadian Ergonomists – about us”. Association of Canadian Ergonomists. 2017. Retrieved 16 May 2018.

- ^ “Mission”. Association of Canadian Ergonomists. 2017. Retrieved 16 May 2018.

- ^ “About HFTH | About Human Factors Transforming Healthcare”.

- ^ “Learning Center – Human Factors and Ergonomics – SAE MOBILUS”. saemobilus.sae.org. Retrieved 15 March 2021.

- ^ Smithsonian Education. Carbon to Computers. (1998) A Short History of the Birth and Growth of the American Office. http://www.smithsonianeducation.org/scitech/carbons/text/birth.html

- ^ Jastrzębowski, W. B., Koradecka, D., (2000) An outline of ergonomics, or the science of work based upon the truths drawn from the Science of Nature: 1857 International Ergonomics Association., & Human Factors and Ergonomics Society. (2000).. Warsaw: Central Institute for Labour Protection.

- ^ Hewes, G (1955). “World Distribution of Certain Postural Habits”. American Anthropologist. 57 (2): 231–244. doi:10.1525/aa.1955.57.2.02a00040. JSTOR 666393.

- ^ C. Dimitri, A. Effland, and N. Conklin, (2005) The 20th Century Transformation of U.S. Agriculture and Farm Policy, Economic Information Bulletin Number

- ^ Wyatt, I. D. (2006). “Occupational changes during the 20th century”. Monthly Lab. Rev. 129: 35.

- ^ Roughton, James E. (2003). “Occupational Injury and Illness Recording and Reporting Requirements, Part 1904”. OSHA 2002 Recordkeeping Simplified. Elsevier. pp. 48–147. doi:10.1016/b978-075067559-8/50029-6. ISBN 9780750675598.

- ^ de Rezende, Leandro Fornias Machado; Rey-López, Juan Pablo; Matsudo, Victor Keihan Rodrigues; do Carmo Luiz, Olinda (9 April 2014). “Sedentary behavior and health outcomes among older adults: a systematic review”. BMC Public Health. 14: 333. doi:10.1186/1471-2458-14-333. ISSN 1471-2458. PMC 4021060. PMID 24712381.

- ^ Parry, Sharon; Straker, Leon (2013). “The contribution of office work to sedentary behaviour associated risk”. BMC Public Health. 13: 296. doi:10.1186/1471-2458-13-296. PMC 3651291. PMID 23557495.

- ^ Jump up to:a b Canadian Centre for Occupational Health. (2019, March 15). (none). Retrieved February, 2019, from https://www.ccohs.ca/oshanswers/ergonomics/sitting/sitting_overview.html

- ^ Jump up to:a b c Konevic, S.; Martinovic, J.; Djonovic, N. (2015). “Association of Socioeconomic Factors and Sedentary Lifestyle in Belgrade’s Suburb, Working Class Community”. Iranian Journal of Public Health. 44 (8): 1053–60. PMC 4645725. PMID 26587469.

- ^ Yang, Lin; Hipp, J. Aaron; Lee, Jung Ae; Tabak, Rachel G.; Dodson, Elizabeth A.; Marx, Christine M.; Brownson, Ross C. (2017). “Work-related correlates of occupational sitting in a diverse sample of employees in Midwest metropolitan cities”. Preventive Medicine Reports. 6: 197–202. doi:10.1016/j.pmedr.2017.03.008. PMC 5374873. PMID 28373929.

- ^ Jump up to:a b Polanyi, M. F.; Cole, D. C.; Ferrier, S. E.; Facey, M.; Worksite Upper Extremity Research Group (March 2005). “Paddling upstream: A contextual analysis of implementation of a workplace ergonomic policy at a large newspaper”. Applied Ergonomics. 36 (2): 231–239. doi:10.1016/j.apergo.2004.10.011. PMID 15694078.

- ^ Jump up to:a b “Ergonomics Policy”. risk.nv.gov. Retrieved 28 March 2019.

- ^ Stanton, N.; Salmon, P.; Walker G.; Baber, C.; Jenkins, D. (2005). Human Factors Methods; A Practical Guide For Engineering and Design. Aldershot, Hampshire: Ashgate Publishing Limited. ISBN 978-0-7546-4661-7.

- ^ Jump up to:a b Carrol, J.M. (1997). “Human-Computer Interaction: Psychology as a Science of Design”. Annual Review of Psychology. 48: 61–83. CiteSeerX 10.1.1.24.5979. doi:10.1146/annurev.psych.48.1.61. PMID 15012476.

- ^ “Survey Methods, Pros & Cons”. Better Office.net. Retrieved 17 April 2014.

- ^ Jump up to:a b c d e Wickens, C.D.; Lee J.D.; Liu Y.; Gorden Becker S.E. (1997). An Introduction to Human Factors Engineering, 2nd Edition. Prentice Hall. ISBN 0-321-01229-1.

- ^ Bruno, Fabio; Barbieri, Loris; Muzzupappa, Maurizio (2020). “A Mixed Reality system for the ergonomic assessment of industrial workstations”. International Journal on Interactive Design and Manufacturing. 14 (3): 805–812. doi:10.1007/s12008-020-00664-x. S2CID 225517293.

- ^ Kuusela, H.; Paul, P. (2000). “A comparison of concurrent and retrospective verbal protocol analysis”. The American Journal of Psychology. 113 (3): 387–404. doi:10.2307/1423365. JSTOR 1423365. PMID 10997234.

- ^ Obinna P. Fidelis, Olusoji A. Adalumo, Ephraim O. Nwoye (2018). Ergonomic Suitability of Library Readers’ Furniture in a Nigerian University; AJERD Vol 1, Issue 3,366-370

- ^ Jump up to:a b Thomas J. Armstrong (2007). Measurement and Design of Work.

- ^ Miller, Doug (2013). “Towards Sustainable Labour Costing in UK Fashion Retail”. Social Science Research Network. doi:10.2139/ssrn.2212100.

- ^ Jump up to:a b c d e f g h i Brookhuis, K., Hedge, A., Hendrick, H., Salas, E., and Stanton, N. (2005). Handbook of Human Factors and Ergonomics Models. Florida: CRC Press.

- ^ Ben-Gal; et al. (2002). “The Ergonomic Design of Workstation Using Rapid Prototyping and Response Surface Methodology” (PDF). IIE Transactions on Design and Manufacturing. 34 (4): 375–391. doi:10.1080/07408170208928877. S2CID 214650306. Archived from the original (PDF) on 21 July 2011. Retrieved 19 July 2012.

- ^ Hornbaek, K (2006). “Current Practice in Measuring Usability: Challenges to Usability Studies and Research”. International Journal of Human-Computer Studies. 64 (2): 79–102. doi:10.1016/j.ijhcs.2005.06.002. S2CID 2615818.

- ^ Dumas, J. S.; Salzman, M. C. (2006). Reviews of Human Factors and Ergonomics. Vol. 2. Human Factors and Ergonomics Society.

Recommended HashTags

- #officedesign

- #wellness

- #interiordesign

- #backpain

- #ergonomicchair

- #neckpain

- #health

- #ergonomicsolutions

- #officesetup

- #work

- #workspacedesign

- #wfh

- #workstation

- #workspacegoals

- #physicaltherapy

- #ergonomicseating

- #furniture

- #setupinspiration

- #technology

- #hightechnology