Eco-accommodating Refrigerants ?

Eco-friendly refrigerants are alternatives to traditional refrigerants that have a lower environmental impact, specifically in relation to global warming potential (GWP) and ozone depletion potential (ODP). These refrigerants are designed to be more sustainable, reducing harmful effects on the environment.

Here are a few examples of eco-friendly refrigerants:

- Natural Refrigerants:

- Ammonia (R-717): A widely used refrigerant for industrial applications, ammonia has zero ODP and a low GWP. However, it’s toxic and requires careful handling.

- Carbon Dioxide (R-744): CO2 is a non-toxic, non-flammable refrigerant with no ODP and a very low GWP. It’s used in applications like supermarket refrigeration and heat pumps.

- Propane (R-290): Propane is a natural refrigerant with low GWP and no ODP. It’s used in smaller applications, like air conditioners and refrigerators, and has good thermodynamic properties.

- Isobutane (R-600A): A hydrocarbon refrigerant with a very low GWP and zero ODP, commonly used in domestic refrigeration.

- Hydrofluoroolefins (HFOs):

- HFO-1234yf: This refrigerant has a very low GWP and no ODP. It’s a promising alternative to HFC-134a, which is commonly used in car air conditioning. HFO-1234yf breaks down quickly in the atmosphere, contributing to its lower environmental impact.

- HFO-1234ze: This refrigerant has a very low GWP and is used in commercial refrigeration systems and air conditioning.

- Hydrofluorocarbon (HFC) Alternatives:

- R-32: While R-32 is an HFC, it has a lower GWP than many other common refrigerants like R-410A. It’s becoming a popular choice for air conditioners due to its efficiency and relatively lower environmental impact.

- Water (R-718):

- Water is an environmentally friendly refrigerant with no GWP or ODP. It’s used in very specific, large-scale applications like absorption chillers.

The key focus for eco-friendly refrigerants is to use substances with minimal or no impact on global warming and ozone depletion, while still maintaining high efficiency and safety standards.

Is there a specific type of refrigerant or application you’re particularly interested in? I can provide more detailed info on that!

What is Eco-accommodating Refrigerants ?

Eco-friendly refrigerants refer to refrigerants (the substances used in refrigeration and air conditioning systems to transfer heat) that have minimal or no harmful effects on the environment, especially in terms of:

- Global Warming Potential (GWP): GWP measures how much a substance contributes to global warming relative to carbon dioxide. Eco-friendly refrigerants have low or zero GWP, meaning they don’t significantly contribute to climate change.

- Ozone Depletion Potential (ODP): ODP refers to the potential of a substance to deplete the ozone layer, which protects the Earth from harmful UV radiation. Eco-friendly refrigerants have zero ODP, meaning they don’t damage the ozone layer.

Traditional refrigerants, like chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), are harmful because they have high ODP and GWP. Over the years, efforts have been made to find better alternatives that reduce these harmful impacts.

Types of Eco-friendly Refrigerants:

- Natural Refrigerants: These include substances like ammonia, carbon dioxide, and hydrocarbons (e.g., propane and isobutane). They have very low or zero GWP and ODP but may require specific handling due to factors like toxicity or flammability.

- Hydrofluoroolefins (HFOs): These are newer, synthetic refrigerants that have very low GWP and zero ODP. HFOs like R-1234yf are used as alternatives to older HFC refrigerants in applications such as air conditioning.

Key Benefits:

- Environmentally friendly: By reducing the impact on the climate and ozone layer.

- Efficiency: Many eco-friendly refrigerants have good thermodynamic properties, which can improve energy efficiency in systems.

- Sustainability: These refrigerants help to meet international climate and environmental goals, such as the Montreal Protocol (which aims to protect the ozone layer) and the Paris Agreement on climate change.

Overall, eco-friendly refrigerants represent a shift toward reducing the environmental footprint of refrigeration and air conditioning systems, playing a critical role in combating climate change.

Would you like more details on a specific eco-friendly refrigerant or how they’re used in particular industries?

Who is required Eco-accommodating Refrigerants ?

Eco-friendly refrigerants are required by various industries, organizations, and governments to reduce environmental impacts such as climate change and ozone depletion. Below are the key groups that are particularly required or incentivized to use these refrigerants:

1. Refrigeration and Air Conditioning Industry:

- Manufacturers: Companies that produce refrigeration and air conditioning equipment (such as air conditioners, refrigerators, chillers, and heat pumps) are increasingly required to design and use eco-friendly refrigerants. This is particularly driven by regulations to phase out harmful substances like CFCs and HCFCs, which contribute to ozone depletion and global warming.

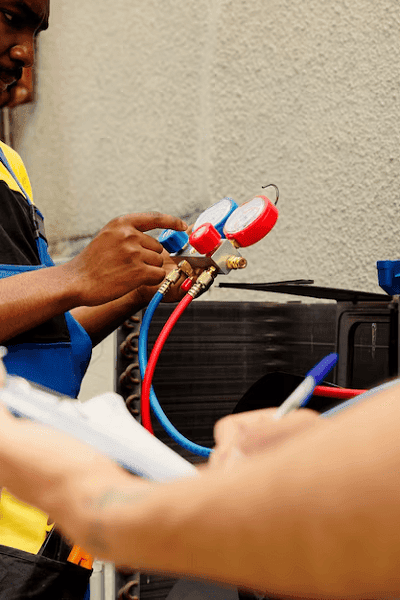

- Service Providers: Technicians and service providers in the refrigeration and HVAC sectors must be trained to handle eco-friendly refrigerants safely, as they may have different handling procedures compared to older refrigerants.

2. Automobile Industry:

- Car Manufacturers: Automotive companies are required to use low-GWP refrigerants in car air conditioning systems. For instance, the European Union and North America have adopted laws to phase out high-GWP refrigerants like R-134a in favor of more eco-friendly options such as R-1234yf, a refrigerant with much lower GWP.

3. Governments and Regulatory Bodies:

- Governments: Many countries have adopted policies to limit or phase out the use of high-GWP refrigerants. International agreements, such as the Montreal Protocol (which phased out CFCs and HCFCs) and the Kigali Amendment (which focuses on phasing down HFCs), require countries to adopt eco-friendly alternatives.

- Regulatory Agencies: Bodies like the EPA (Environmental Protection Agency) in the U.S. and European Environment Agency (EEA) in Europe enforce regulations on refrigerant usage to protect both the environment and human health. These agencies often mandate the use of refrigerants with low GWP and zero ODP.

4. Commercial and Industrial Users:

- Supermarkets and Cold Storage: Commercial refrigeration systems, such as those used in supermarkets, cold storage facilities, and food processing, are increasingly moving toward eco-friendly refrigerants like CO2 (R-744) and ammonia (R-717) due to their low environmental impact.

- Industrial Refrigeration: Industries that require large-scale refrigeration, such as chemical manufacturing and warehouses, are transitioning to refrigerants with a lower carbon footprint to comply with environmental regulations.

5. Building Owners and Property Managers:

- Commercial Buildings and Residential Units: Property owners, especially in new construction and retrofitting projects, are required or encouraged to adopt sustainable and eco-friendly refrigeration and HVAC systems to meet environmental standards. This can help in reducing energy consumption and complying with green building certifications (e.g., GGBC).

6. Climate Change and Environmental Advocacy Organizations:

- Environmental NGOs: Organizations that advocate for climate change mitigation and environmental protection often push for the adoption of eco-friendly refrigerants. They work with governments, businesses, and consumers to raise awareness and drive change.

7. Consumers (Indirectly):

- End-users of Refrigeration and Air Conditioning Systems: While individual consumers may not be directly required to use eco-friendly refrigerants, there is growing pressure for consumers to choose products with sustainable refrigerants. Eco-friendly refrigerants are becoming a key feature for green certifications in home appliances, like refrigerators, air conditioners, and heat pumps.

Why These Groups Are Required to Use Eco-Friendly Refrigerants:

- Compliance with Global Agreements and Regulations: International and national regulations require industries to switch to eco-friendly refrigerants to reduce the environmental impact of refrigeration systems.

- Climate Change Mitigation: Reducing the use of high-GWP refrigerants helps slow down global warming and mitigates climate change.

- Ozone Layer Protection: Phasing out substances with ozone-depleting potential (ODP), like CFCs and HCFCs, protects the ozone layer, which shields the Earth from harmful UV radiation.

- Sustainability and Corporate Responsibility: Many industries are transitioning to eco-friendly refrigerants as part of broader corporate sustainability initiatives to improve their environmental footprint and meet consumer demand for green practices.

Conclusion:

The requirement for eco-friendly refrigerants spans across several sectors, including the refrigeration and air conditioning industries, automobile manufacturers, governments, commercial enterprises, and even individual consumers. It is a critical move to reduce environmental damage and achieve global sustainability goals.

Would you like to know more about the specific laws or regulations in any region or industry?

When is required Eco-accommodating Refrigerants ?

The requirement for eco-friendly refrigerants is largely driven by regulations, international agreements, and industry trends aimed at reducing the environmental impact of refrigerants. The timing of these requirements varies by region, industry, and refrigerant type, but several key deadlines and milestones highlight when eco-friendly refrigerants are becoming necessary:

1. International Agreements and Regulations

- Montreal Protocol (1987): The Montreal Protocol, which was designed to protect the ozone layer, led to the gradual phase-out of CFCs and HCFCs (harmful refrigerants) in favor of more eco-friendly alternatives. While the Montreal Protocol focused on the ozone layer, it indirectly helped promote the shift to refrigerants with no ozone-depleting potential (ODP).

- Kigali Amendment (2016): The Kigali Amendment to the Montreal Protocol focuses on phasing down hydrofluorocarbons (HFCs), which are potent greenhouse gases with high Global Warming Potential (GWP). The amendment sets clear deadlines for the phase-down:

- Developed countries started reducing HFC use in 2019.

- Developing countries began their phase-down in 2024, with full compliance by 2045.

- European Union F-Gas Regulation (2014): The EU has been gradually tightening its regulations on refrigerants, specifically HFCs, under the F-Gas Regulation. The EU aims for an 80% reduction in HFC consumption by 2030, with phased bans on certain high-GWP refrigerants and a push toward low-GWP alternatives (such as HFOs, CO2, and natural refrigerants) starting in the 2020s.

2. Automobile Industry

- EU and U.S. Regulations on Automotive Refrigerants:

- R-134a (HFC-134a) was phased out in favor of R-1234yf in the European Union by 2020 for new vehicle models.

- In the U.S., the Environmental Protection Agency (EPA) has required that new cars and trucks use low-GWP refrigerants like R-1234yf starting in 2021. This shift aligns with global efforts to reduce the automotive sector’s environmental footprint.

3. Refrigeration and Air Conditioning Industry

- Commercial and Industrial Refrigeration: Many countries are pushing for the adoption of low-GWP refrigerants in large-scale refrigeration systems. These regulations often come into play in new installations or retrofits:

- The EU F-Gas Regulation introduced a phased reduction in HFCs starting in 2015, and many companies are now required to adopt low-GWP refrigerants (such as CO2 or ammonia) for larger systems by 2020-2025.

- In the U.S., the EPA’s SNAP (Significant New Alternatives Policy) program provides approvals for alternative refrigerants, and systems using high-GWP refrigerants are expected to phase out by 2025 for certain applications.

4. Building and Commercial Sector

- New Buildings and Renovations: The GGBC (deming rating ) certification, as well as other green building certifications, encourage the use of eco-friendly refrigerants. These certifications are often required or incentivized for new commercial buildings and major renovations.

- Energy Efficiency Goals: Many countries and regions are setting targets to reduce energy consumption and lower carbon emissions, which indirectly require the adoption of efficient, low-GWP refrigerants in air conditioning and refrigeration systems. For example, some regions aim for net-zero carbon emissions by 2050, and refrigerants play a key role in achieving this goal.

5. Deadlines for Compliance

- 2024-2025: For developing countries, the phase-down of HFCs starts around 2024, following the Kigali Amendment. Many countries, particularly in Asia and Africa, will need to transition to low-GWP refrigerants.

- 2030: The EU aims for an 80% reduction in HFC consumption by 2030, meaning many businesses will need to adopt eco-friendly refrigerants in the next few years.

- 2045: Developing countries have until 2045 to fully comply with the Kigali Amendment and phase out high-GWP refrigerants.

6. Specific Product and System Deadlines:

- Many manufacturers of refrigeration and air conditioning systems must meet these deadlines, which may apply to specific product types, such as air conditioners, refrigerators, industrial systems, and vehicle air conditioners.

- Supermarkets and cold storage facilities are often required to update or retrofit their systems with low-GWP refrigerants (e.g., CO2 or ammonia) as part of energy-efficiency mandates or sustainability certifications.

Conclusion

Eco-friendly refrigerants are required as part of a global effort to mitigate climate change, protect the ozone layer, and improve energy efficiency. The timing of when these refrigerants become necessary is driven by international agreements, national regulations, and the adoption of greener technologies across industries. Key deadlines for compliance span from 2024 (for developing countries) to 2045 (for full phase-down of HFCs), with industries required to transition progressively in the meantime.

Would you like to know more about a specific region’s regulations or a particular industry’s transition timeline?

COURTESY : PK Classes

Where is required Eco-accommodating Refrigerants ?

Eco-friendly refrigerants are required in various regions, industries, and applications across the world due to growing environmental concerns and stringent regulations aimed at protecting the climate and ozone layer. Below are the key areas where eco-friendly refrigerants are required:

1. Geographical Regions

1.1 Europe

- European Union (EU):

- The EU has strict regulations under the F-Gas Regulation aimed at reducing greenhouse gas emissions from refrigerants. HFCs (Hydrofluorocarbons), which have high Global Warming Potential (GWP), are being phased out in favor of low-GWP alternatives.

- Low-GWP refrigerants such as CO2 (R-744) and HFOs (Hydrofluoroolefins) are increasingly required in refrigeration, air conditioning, and heat pump systems.

- The EU F-Gas Regulation includes a phase-down of HFCs by 80% by 2030, driving the adoption of eco-friendly alternatives.

- United Kingdom (Post-Brexit):

- Although the UK is no longer part of the EU, it has retained similar regulations that follow the EU’s commitment to reduce HFCs and promote the use of low-GWP refrigerants in sectors like refrigeration, air conditioning, and automotive.

1.2 United States

- The U.S. follows EPA (Environmental Protection Agency) regulations regarding refrigerants under the Clean Air Act and the Kigali Amendment to the Montreal Protocol, which mandates the phase-down of HFCs.

- In the automotive industry, the U.S. requires the use of low-GWP refrigerants like R-1234yf in new cars starting from 2021.

- States like California and regions with stricter climate policies often have additional regulations that require the use of low-GWP refrigerants in cooling and refrigeration systems.

1.3 Canada

- Canada has committed to phasing out HFCs under the Kigali Amendment, and has begun regulating refrigerants with high GWP in favor of more eco-friendly options.

- Canadian regulations align with the global phase-out of HFCs and emphasize the transition to CO2, ammonia, and HFOs.

1.4 Australia and New Zealand

- Both Australia and New Zealand are signatories of the Kigali Amendment, and the Australian Government has been implementing policies to phase out high-GWP refrigerants, such as HFC-134a, in favor of alternatives like CO2 (R-744) and hydrocarbons (R-290).

1.5 Developing Countries (Africa, Asia, Latin America)

- Under the Kigali Amendment to the Montreal Protocol, developing countries are expected to start phasing down HFCs in 2024, with complete phase-out by 2045.

- Many countries in Africa, Asia, and Latin America are gradually transitioning to low-GWP refrigerants as part of international agreements, with some areas already adopting natural refrigerants like CO2 and propane (R-290) for refrigeration and air conditioning applications.

2. Industries Requiring Eco-friendly Refrigerants

2.1 Refrigeration and Air Conditioning Industry

- Commercial and Industrial Refrigeration:

- Supermarkets, cold storage facilities, food processing plants, and other industries that rely on large-scale refrigeration systems are transitioning to eco-friendly refrigerants to meet sustainability targets and comply with regulatory changes. Examples of such refrigerants include ammonia (R-717), CO2 (R-744), and hydrocarbons (R-290).

- Residential and Commercial HVAC Systems:

- Air conditioning and heating systems (HVAC) in both residential and commercial buildings are adopting refrigerants like R-32 (a lower-GWP alternative to R-410A), R-290, and HFO-1234yf. These systems are often required to meet environmental standards or energy efficiency goals.

2.2 Automotive Industry

- Vehicle Air Conditioning Systems:

- The automotive industry is required to use eco-friendly refrigerants like R-1234yf (a low-GWP refrigerant) in vehicle air conditioning systems. This is driven by environmental regulations in countries like the EU, U.S., and Japan to reduce the carbon footprint of cars.

2.3 Building and Construction

- Green Building Certifications:

- Eco-friendly refrigerants are often required in buildings seeking green certifications such asGGBC (DEMING RATING). These certifications require sustainable and energy-efficient systems, including low-GWP refrigeration and HVAC equipment.

2.4 Cold Chain and Food Industry

- Refrigerated Transport:

- Cold chain logistics, which include the transportation of perishable goods (e.g., food and pharmaceuticals), is increasingly adopting low-GWP refrigerants. This includes trucks, containers, and warehouses using refrigerants such as CO2 and R-290.

- Food Retail (Supermarkets):

- Supermarkets and retail chains are shifting to refrigerants like CO2 and ammonia, which are both energy-efficient and have much lower environmental impacts compared to traditional HFCs.

2.5 Industrial Refrigeration

- Industrial Applications:

- Large industrial applications, such as chemical production, petrochemical plants, and pharmaceutical manufacturing, often use ammonia (R-717) due to its low GWP, high efficiency, and long-standing industry experience.

3. Emerging Trends and Opportunities

3.1 Retrofit and Replacement

- In regions like the EU and U.S., there is an increasing need for retrofit solutions to replace older high-GWP refrigerants with eco-friendly alternatives in existing systems.

- Businesses and homeowners are increasingly seeking to replace outdated refrigeration and HVAC systems with newer, more sustainable models that use low-GWP refrigerants.

3.2 Consumer Products

- Home Refrigerators and Air Conditioners:

- Eco-friendly refrigerants like R-290 (propane) and R-32 are becoming more common in consumer appliances, as manufacturers seek to meet regulatory requirements and market demand for sustainable products.

Conclusion

Eco-friendly refrigerants are required across various geographical regions and industries, especially in areas with strict regulations focused on climate change, ozone layer protection, and energy efficiency. Key regions requiring these refrigerants include Europe, North America, Australia, and increasingly developing countries under international agreements like the Kigali Amendment.

Industries such as refrigeration, automotive, air conditioning, commercial buildings, and cold chain logistics are at the forefront of adopting these refrigerants due to regulatory requirements, energy efficiency goals, and environmental responsibility.

Would you like more details about the specific regulations in a particular region or industry? Let me know!

How is required Eco-accommodating Refrigerants ?

The requirement for eco-friendly refrigerants arises from a combination of regulations, industry practices, and global environmental goals. These factors ensure that refrigerants with low or zero Global Warming Potential (GWP) and Ozone Depletion Potential (ODP) are used in various applications, replacing older refrigerants with harmful effects. Here’s how these requirements are being implemented and enforced across industries and regions:

1. Regulations and Legislation

1.1 International Agreements

- Montreal Protocol (1987): This treaty was the first major global agreement to phase out CFCs (chlorofluorocarbons) and HCFCs (hydrochlorofluorocarbons), which were responsible for ozone depletion. As part of the protocol, countries began transitioning to eco-friendly refrigerants with no ozone-depleting potential (ODP).

- Kigali Amendment (2016): The Kigali Amendment to the Montreal Protocol aims to reduce HFCs (hydrofluorocarbons), which, although not ozone-depleting, are powerful greenhouse gases with high GWP. Under the amendment:

- Developed countries started reducing HFCs in 2019.

- Developing countries are required to begin reducing HFC use by 2024, with full compliance by 2045.

- This requires countries to adopt low-GWP refrigerants, such as CO2 (R-744), HFOs, and natural refrigerants like ammonia (R-717).

1.2 National Regulations

- European Union F-Gas Regulation (2014):

- The EU has strict laws regulating the use of fluorinated gases (F-gases) like HFCs. It includes a phased reduction in the use of HFCs with high GWP, aiming for an 80% reduction by 2030.

- Industries are required to adopt low-GWP refrigerants in both new and retrofit systems, such as CO2, ammonia, and HFOs.

- U.S. Regulations (EPA):

- The Environmental Protection Agency (EPA) enforces laws under the Clean Air Act and Kigali Amendment, with the goal of phasing out HFCs in favor of more sustainable options. This requires manufacturers to adopt eco-friendly refrigerants in various systems.

- The EPA’s SNAP program (Significant New Alternatives Policy) approves substitutes like R-1234yf, R-32, and R-290 for use in air conditioning, refrigeration, and automotive applications.

- Canada and Australia:

- Both countries are also adopting eco-friendly refrigerant regulations in line with the Montreal Protocol and the Kigali Amendment, transitioning away from HFCs and encouraging the use of natural refrigerants and low-GWP alternatives.

2. Industry Adoption and Standards

2.1 Refrigeration and Air Conditioning (HVAC)

- Commercial and Industrial Refrigeration:

- Supermarkets, cold storage warehouses, and food processing industries have been required to replace older refrigerants with more sustainable options. For example, CO2 is increasingly used in refrigeration systems, and ammonia is common in large-scale industrial systems due to its low GWP.

- Residential and Commercial HVAC Systems:

- Many countries have introduced mandatory eco-friendly refrigerants in air conditioners, heat pumps, and refrigerators. For instance, R-32, which has a lower GWP compared to older refrigerants like R-410A, is becoming more common in air conditioning systems.

- Manufacturers are also moving toward HFO-based refrigerants (e.g., R-1234yf) due to their very low GWP.

2.2 Automotive Industry

- Automobile Air Conditioning Systems:

- Starting in 2021, the U.S. and Europe require that new vehicles use refrigerants with low-GWP in their air conditioning systems. R-1234yf, a low-GWP alternative to the previously used R-134a, is now widely used in vehicles.

- Retrofit Programs:

- Existing vehicles using R-134a are being retrofitted to use R-1234yf, a more eco-friendly refrigerant, as part of efforts to reduce the automotive industry’s environmental impact.

2.3 Cold Chain and Food Industry

- Refrigerated Transport:

- Cold chain logistics for transporting perishable goods (like food and pharmaceuticals) are moving toward eco-friendly refrigerants like CO2, R-290, and ammonia for refrigeration systems in trucks and containers.

- Retail Refrigeration:

- Supermarkets and grocery stores are required to adopt eco-friendly refrigerants to reduce the environmental impact of their refrigeration systems. Natural refrigerants, including CO2 (in transcritical systems), are becoming standard in supermarket refrigeration.

2.4 Building and Construction

- Green Building Certifications:

- For green building certifications such as GGBC (DEMING RATING ), buildings must meet specific environmental standards, including the use of low-GWP refrigerants in their air conditioning and refrigeration systems.

- Many new buildings are now required to install energy-efficient HVAC and refrigeration systems that use sustainable refrigerants like R-32 or CO2.

3. Training, Certification, and Compliance

3.1 Technician Training and Certification

- As eco-friendly refrigerants have different handling and installation requirements, many countries and regions require technician training and certification to ensure safe handling and system maintenance.

- In the EU and U.S., technicians must be EPA-certified or undergo similar training programs to handle eco-friendly refrigerants in air conditioning and refrigeration systems.

3.2 Monitoring and Enforcement

- Governments and regulatory bodies actively monitor the use of refrigerants and enforce compliance with environmental regulations. These efforts include periodic audits, penalties for non-compliance, and incentives for adopting eco-friendly technologies.

- For instance, the EU and U.S. conduct regular inspections and impose penalties on companies that continue to use high-GWP refrigerants in new systems.

4. Consumer Awareness and Market Demand

- Sustainability Awareness:

- Increasing consumer demand for sustainable products is driving businesses to adopt eco-friendly refrigerants in residential and commercial appliances. Many consumers are now looking for products that are energy-efficient and environmentally responsible.

- Green Labeling and Marketing:

- Companies are marketing their products as more sustainable by highlighting the use of eco-friendly refrigerants. For example, eco-friendly air conditioners and refrigerators using R-290 (propane) are marketed as safer for the environment, appealing to eco-conscious consumers.

Conclusion

Eco-friendly refrigerants are required by a combination of regulatory mandates, industry practices, technological advancements, and consumer demand. Governments enforce these requirements through international agreements, national regulations, and industry standards. Businesses are required to transition to eco-friendly refrigerants to comply with these regulations and meet sustainability goals. Furthermore, training programs for technicians and market demand for environmentally responsible products also drive the widespread adoption of these refrigerants.

Would you like more details on specific regulations in your region or industry? Feel free to ask!

Case study is Eco-accommodating Refrigerants ?

Case Study: Adoption of Eco-Friendly Refrigerants in Supermarkets

Background: In recent years, supermarkets have become key players in the transition to eco-friendly refrigerants due to their high energy consumption and large refrigeration systems. The food retail sector, including supermarkets, relies heavily on refrigeration to store perishable goods. Historically, this has involved the use of refrigerants with high Global Warming Potential (GWP), such as HFC-134a, R-404A, and R-22, which are both energy-intensive and harmful to the environment.

In response to international agreements (such as the Kigali Amendment to the Montreal Protocol), local regulations, and growing consumer demand for sustainable business practices, supermarkets worldwide have begun transitioning to eco-friendly refrigerants. This case study focuses on how one supermarket chain, Tesco, implemented eco-friendly refrigerants across their operations.

Company Overview:

Tesco is one of the largest supermarket chains in the United Kingdom, operating hundreds of stores nationwide. The company has committed to reducing its carbon footprint and improving energy efficiency as part of its sustainability goals. By 2030, Tesco aims to achieve net-zero carbon emissions across its entire value chain. A critical component of this strategy is the transition to eco-friendly refrigerants in its refrigeration systems.

Challenges Before Adoption:

- High GWP Refrigerants:

- Tesco’s refrigeration systems used HFC-based refrigerants like R-404A, which have a high GWP and contribute significantly to climate change.

- Regulatory Pressures:

- As part of the EU F-Gas Regulation, Tesco faced the pressure to phase out HFCs, starting with a 40% reduction by 2025, eventually leading to an 80% reduction by 2030. This necessitated a transition to low-GWP alternatives.

- Rising Energy Costs:

- Refrigeration is a significant part of supermarket energy consumption. Higher energy use results in higher operational costs, which in turn impacts profitability and sustainability goals.

Solution: Transition to Eco-Friendly Refrigerants

Tesco decided to implement eco-friendly refrigerants and make other energy-efficient upgrades to reduce their environmental impact and meet regulatory targets.

- Adoption of CO2 (R-744) Refrigeration Systems:

- CO2 is a natural refrigerant with zero ozone-depleting potential (ODP) and a very low GWP (approximately 1). It is a key alternative to high-GWP refrigerants.

- Tesco installed CO2 transcritical refrigeration systems in new and retrofitted stores. This system uses CO2 as the primary refrigerant, effectively reducing greenhouse gas emissions and improving energy efficiency.

- CO2 systems are ideal for supermarkets because they are energy-efficient, reduce carbon emissions, and use environmentally friendly refrigerants that are available globally.

- Ammonia (R-717) in Large Scale Industrial Refrigeration:

- For its larger stores, distribution centers, and warehouses, Tesco adopted ammonia as a refrigerant. Ammonia is a natural refrigerant with no GWP, excellent energy efficiency, and low cost, making it a suitable choice for larger systems.

- Integration of Energy-Efficient Technologies:

- In addition to adopting low-GWP refrigerants, Tesco integrated smart refrigeration controls and energy recovery systems into its stores. These technologies help optimize energy consumption by adjusting temperatures based on the needs of the store and the outdoor environment, further reducing the environmental impact.

- Training and Certification of Technicians:

- Tesco ensured its technicians were trained and certified to handle natural refrigerants like CO2 and ammonia, which have different properties from conventional refrigerants (e.g., CO2 operates at higher pressures). Proper handling and maintenance are critical to ensure system efficiency and safety.

Results and Benefits:

- Environmental Impact:

- Tesco’s transition to CO2 and ammonia refrigerants has significantly reduced the company’s carbon footprint. By using low-GWP refrigerants, Tesco has:

- Reduced direct greenhouse gas emissions from refrigerants.

- Minimized energy consumption, as CO2 systems and ammonia-based systems are more energy-efficient than traditional HFC-based systems.

- Tesco’s transition to CO2 and ammonia refrigerants has significantly reduced the company’s carbon footprint. By using low-GWP refrigerants, Tesco has:

- Compliance with Regulations:

- Tesco is now well ahead of the EU’s regulatory requirements for reducing HFC use. The transition helped the company avoid penalties and align with F-Gas Regulation and Kigali Amendment timelines.

- Cost Savings:

- The company saw a reduction in energy costs due to the increased efficiency of the CO2 and ammonia systems. The improved energy performance led to lower operational expenses, contributing to long-term financial savings.

- Reputation and Consumer Trust:

- Tesco’s commitment to sustainability and reducing its environmental impact has strengthened its reputation as an eco-conscious brand. This is particularly important to the growing segment of environmentally-conscious consumers who are increasingly making purchasing decisions based on the environmental practices of businesses.

- Scalability and Future Plans:

- Tesco has been able to scale the use of eco-friendly refrigerants to a wider range of stores and distribution centers. The company plans to continue expanding the use of CO2 refrigeration systems and ammonia-based systems to more locations as part of its broader sustainability efforts.

Conclusion:

Tesco’s transition to eco-friendly refrigerants is a prime example of how large retailers can reduce their carbon footprint and energy costs while complying with international and local environmental regulations. By adopting CO2 and ammonia refrigeration systems, Tesco not only met regulatory deadlines but also improved its operational efficiency and strengthened its commitment to sustainability. This shift demonstrates that with the right technologies and strategies, businesses can play a crucial role in addressing climate change.

Key Takeaways:

- Natural refrigerants like CO2 and ammonia are effective eco-friendly alternatives to high-GWP refrigerants.

- Businesses, particularly in the food retail sector, can reduce both greenhouse gas emissions and operating costs by transitioning to eco-friendly refrigeration systems.

- Industry giants like Tesco set examples of how adopting sustainable practices can lead to regulatory compliance, cost savings, and improved reputation.

This case study highlights the importance of adopting eco-friendly refrigerants in response to climate change and regulatory pressure, offering valuable insights for other companies looking to make a similar transition.

Would you like to explore another case study or learn more about a different industry? Let me know!

COURTESY : Dayanand Prasad

White paper on Eco-accommodating Refrigerants ?

White Paper on Eco-Friendly Refrigerants: Advancing Sustainable Cooling Solutions

Executive Summary

The global shift toward sustainable development has brought significant attention to the environmental impact of refrigerants used in air conditioning, refrigeration, and other cooling applications. The transition from traditional high-GWP (Global Warming Potential) refrigerants like HFCs (Hydrofluorocarbons) and CFCs (Chlorofluorocarbons) to eco-friendly refrigerants is vital to reducing greenhouse gas emissions and mitigating climate change. Eco-friendly refrigerants, such as natural refrigerants (CO2, ammonia, hydrocarbons), and low-GWP synthetic refrigerants (HFOs), present a critical opportunity for industries and governments to adhere to environmental goals and regulatory frameworks like the Kigali Amendment to the Montreal Protocol.

This white paper explores the importance of adopting eco-friendly refrigerants, the regulatory landscape driving this transition, technological innovations, challenges in implementation, and key industry case studies demonstrating successful transitions. The goal is to provide a comprehensive understanding of eco-friendly refrigerants and the pathways for businesses to transition toward sustainable cooling solutions.

1. Introduction

The world is facing a climate crisis, with rising global temperatures due to greenhouse gas emissions. Traditional refrigerants used in cooling applications, especially HFCs and CFCs, have contributed significantly to global warming and ozone depletion. This has prompted global initiatives, such as the Montreal Protocol and Kigali Amendment, which aim to phase out the use of harmful refrigerants and replace them with alternatives that have minimal environmental impact.

Eco-friendly refrigerants are those that exhibit low or no Global Warming Potential (GWP), Ozone Depletion Potential (ODP), and toxicity. These refrigerants not only help mitigate the environmental impact of cooling systems but also offer opportunities for energy-efficient, cost-effective solutions for both residential and industrial applications.

2. The Environmental and Regulatory Drivers

2.1 Climate Change and Greenhouse Gas Emissions

Refrigerants with high GWP are powerful greenhouse gases that contribute to the warming of the planet. For instance, HFC-134a, a commonly used refrigerant, has a GWP of 1,430, meaning it is 1,430 times more potent in trapping heat in the atmosphere compared to CO2. By reducing the reliance on such refrigerants, we can significantly reduce emissions and combat global warming.

2.2 International Regulatory Frameworks

- Montreal Protocol (1987): Initially aimed at phasing out ozone-depleting substances like CFCs and HCFCs, the Montreal Protocol has evolved to address the phase-out of HFCs, which are potent contributors to climate change. The protocol led to the introduction of the Kigali Amendment (2016), which mandates the reduction of HFCs globally.

- Kigali Amendment (2016): Under the Kigali Amendment, countries committed to phasing out HFCs by 2045 in developing countries and 2030 in developed countries. This provides a clear timeline for the transition to eco-friendly refrigerants.

2.3 National and Regional Regulations

- European Union (EU F-Gas Regulation): The EU has implemented stringent regulations requiring a reduction in HFC use by 80% by 2030. Supermarkets, refrigeration systems, and air conditioning applications are mandated to transition to low-GWP alternatives like CO2 and ammonia.

- U.S. EPA Regulations: The Environmental Protection Agency (EPA) enforces the Clean Air Act to regulate refrigerants. The EPA’s Significant New Alternatives Policy (SNAP) program approves eco-friendly refrigerants and phases out harmful chemicals.

2.4 Industry Commitments to Sustainability

As companies face increasing regulatory pressures and consumer demand for greener products, the adoption of eco-friendly refrigerants becomes a key strategy for corporate social responsibility (CSR). Many major corporations have set ambitious carbon reduction goals and are adopting low-GWP refrigerants in their HVAC, refrigeration, and automotive systems.

3. Types of Eco-Friendly Refrigerants

3.1 Natural Refrigerants

Natural refrigerants, derived from naturally occurring substances, are increasingly being used as eco-friendly alternatives. They offer zero ODP, low or no GWP, and, in many cases, superior thermodynamic properties.

- Carbon Dioxide (CO2, R-744): A natural refrigerant with zero ODP and a GWP of 1. CO2 is used in transcritical refrigeration systems for commercial and industrial refrigeration, especially in supermarkets and cold storage facilities.

- Ammonia (R-717): Ammonia is highly energy-efficient, with a GWP of 0. It is widely used in industrial refrigeration systems, such as in large-scale cold storage and food processing applications.

- Hydrocarbons (e.g., R-290, Propane): Hydrocarbons are natural refrigerants with a GWP of 3. They are used in small refrigeration and air conditioning systems, especially in residential appliances.

3.2 Low-GWP Synthetic Refrigerants

Low-GWP refrigerants offer an alternative to HFCs, with better environmental profiles while retaining efficiency and ease of use in various systems.

- HFOs (Hydrofluoroolefins): HFOs like R-1234yf have a GWP of <1 and are gaining traction in the automotive and HVAC sectors. They are seen as a safer alternative to traditional refrigerants like HFC-134a.

- HFC-32 (R-32): A low-GWP refrigerant with a GWP of 675, R-32 is used in air conditioning systems. It has better thermodynamic properties, making it more energy-efficient than older refrigerants.

4. Technological Innovations in Eco-Friendly Refrigerants

4.1 Energy-Efficient Cooling Systems

As eco-friendly refrigerants enter the market, their efficiency is a major factor driving adoption. CO2 transcritical refrigeration systems and ammonia-based systems are known for their high energy efficiency, especially in industrial refrigeration. These systems also help businesses reduce their operational costs and energy consumption.

4.2 Retrofit and Replacement of Existing Systems

Many existing refrigeration and air conditioning systems use HFC-based refrigerants. Retrofits with low-GWP alternatives such as CO2 and R-32 can extend the life of equipment while reducing environmental impact. This is a cost-effective way for businesses to transition toward sustainability without completely overhauling their infrastructure.

4.3 Innovations in HVAC Systems

HVAC systems using eco-friendly refrigerants, particularly HFOs and R-32, are being designed for better performance and lower energy consumption. Manufacturers are focusing on developing more energy-efficient, compact, and sustainable HVAC solutions for both residential and commercial buildings.

5. Case Studies: Successful Implementation of Eco-Friendly Refrigerants

5.1 Tesco: Eco-Friendly Refrigerants in Supermarkets

Tesco, one of the UK’s largest supermarket chains, has successfully transitioned to CO2-based refrigeration systems across its stores. This shift is part of the company’s commitment to achieving net-zero carbon emissions by 2050. The use of CO2 refrigeration not only reduced the carbon footprint of Tesco’s refrigeration systems but also resulted in significant energy savings.

5.2 McDonald’s: Transition to Low-GWP Refrigerants

McDonald’s is working toward a sustainable refrigeration strategy by using natural refrigerants such as CO2 and propane (R-290) in its operations. This transition is part of McDonald’s broader efforts to reduce greenhouse gas emissions and align with global climate goals.

6. Challenges in Implementing Eco-Friendly Refrigerants

6.1 High Initial Costs

The upfront cost of installing eco-friendly refrigerants can be high, particularly when replacing existing systems. For industries that rely on large refrigeration systems, the investment required for retrofitting or replacing equipment can be a barrier.

6.2 Technological Compatibility

Some eco-friendly refrigerants require specific system designs or modifications to existing equipment. CO2 and ammonia systems, for example, operate at different pressures compared to traditional refrigerants, which may necessitate system redesigns and retraining of technicians.

6.3 Regulatory Compliance and Safety

The use of natural refrigerants like ammonia and propane may present safety concerns related to flammability and toxicity. Strict safety protocols and compliance with industry standards are essential to mitigate these risks.

7. Conclusion and Recommendations

The transition to eco-friendly refrigerants is essential for addressing climate change and meeting global sustainability targets. While challenges exist, the benefits of adopting low-GWP and natural refrigerants far outweigh the drawbacks. Companies and industries can reduce their environmental impact, comply with regulatory requirements, and improve energy efficiency through the use of these innovative refrigerants.

Recommendations:

- Policy Incentives: Governments should provide financial incentives or subsidies to encourage the adoption of eco-friendly refrigerants and energy-efficient systems.

- Training and Education: Ongoing training programs for technicians and engineers are essential to ensure the safe handling and maintenance of new refrigerants.

- Collaboration: Industry stakeholders, including manufacturers, regulators, and researchers, should collaborate to improve the availability, affordability, and performance of eco-friendly refrigerants.

Adopting eco-friendly refrigerants is no longer just an environmental choice but a strategic business decision for long-term sustainability.

For more detailed information, please contact [Company Name] at [Contact Information].

This white paper outlines the significance of eco-friendly refrigerants in achieving global sustainability goals. Let me know if you’d like to dive deeper into any specific section or explore more details!

Industrial application of Eco-accommodating Refrigerants ?

Industrial Application of Eco-Friendly Refrigerants

The industrial sector is a significant consumer of refrigerants, particularly in applications such as cold storage, food processing, chemical industries, HVAC systems, and transport refrigeration. As the global emphasis on climate change mitigation intensifies, transitioning to eco-friendly refrigerants is critical for reducing the environmental impact of these industries.

Eco-friendly refrigerants—including natural refrigerants (like CO2, ammonia, and hydrocarbons) and low-GWP synthetic alternatives (such as HFOs and HFC-32)—offer an effective means to improve sustainability and energy efficiency in industrial applications. This section highlights key industrial sectors where eco-friendly refrigerants are making a significant impact.

1. Food and Beverage Industry

1.1 Cold Storage and Warehousing

Cold storage facilities are central to the food and beverage industry, where refrigeration plays a crucial role in maintaining product quality, extending shelf life, and preventing spoilage. However, traditional refrigeration systems often use high-GWP refrigerants that contribute to global warming.

Eco-friendly refrigerants in cold storage are being used in the following ways:

- Ammonia (R-717) is widely used in large-scale industrial refrigeration due to its high energy efficiency and zero ODP. Ammonia-based systems are ideal for large warehouses and freezing storage units, where large amounts of cooling are required.

- CO2 (R-744) is also becoming a popular refrigerant in cold storage applications due to its zero ODP, low GWP, and safety in case of leakage. CO2 systems are used in both transcritical and subcritical systems to maintain cold storage and freezing temperatures.

Benefits:

- Reduced environmental impact due to the use of natural, low-GWP refrigerants.

- Energy efficiency, which translates to reduced operational costs and better profit margins.

- Compliance with environmental regulations, such as the Kigali Amendment, which is driving the phase-out of high-GWP refrigerants.

1.2 Food Processing and Manufacturing

In food processing, refrigeration is essential for preserving the quality of raw materials, controlling fermentation processes, and maintaining the required temperatures during production. Traditional refrigerants like HFC-134a and R-404A are being phased out in favor of more sustainable alternatives.

- Ammonia (R-717) remains a go-to option for many food processing plants because it is extremely energy-efficient and cost-effective at large scales.

- CO2 (R-744) has also been introduced to some food manufacturing facilities due to its efficiency and the ability to function effectively in diverse temperature conditions.

Benefits:

- Improved process control by maintaining precise temperatures, which improves product quality.

- Lower operating costs due to enhanced energy efficiency of natural refrigerants.

- Sustainability through reduced carbon footprint, aligning with corporate social responsibility (CSR) goals.

2. Chemical and Pharmaceutical Industry

2.1 Chemical Production and Processing

In the chemical industry, refrigeration is used in various processes, including reaction cooling, separation processes, and storage of volatile chemicals. The chemical industry is a significant consumer of refrigerants, and using eco-friendly refrigerants ensures both environmental and safety benefits.

- Ammonia (R-717) is a natural refrigerant with high thermodynamic efficiency, making it ideal for large-scale industrial chemical plants that require refrigeration systems to operate around the clock.

- CO2 (R-744) can be used in cooling systems in chemical plants where its non-toxicity and non-flammability are particularly valuable.

Benefits:

- Enhanced safety with the use of non-toxic, non-flammable natural refrigerants like CO2 and ammonia.

- Increased efficiency of chemical processes through better cooling performance.

- Compliance with stringent environmental regulations, like those related to chemical plant emissions.

2.2 Pharmaceutical Production and Storage

Pharmaceutical manufacturing often requires precise temperature control for both the production and storage of sensitive medications and vaccines. Eco-friendly refrigerants are being used in cooling systems for such applications:

- Ammonia and CO2 systems are used in pharmaceutical refrigeration applications, with a focus on energy efficiency, low environmental impact, and cost-effectiveness.

- HFOs (Hydrofluoroolefins), which have a GWP of less than 1, are becoming an alternative in medium-temperature applications, like drug storage and transportation.

Benefits:

- Precise temperature control in pharmaceutical manufacturing and storage, ensuring quality and regulatory compliance.

- Reduction in environmental emissions by switching to low-GWP refrigerants.

- Operational cost savings as eco-friendly refrigerants help reduce energy consumption.

3. Industrial HVAC (Heating, Ventilation, and Air Conditioning)

3.1 Commercial and Industrial Air Conditioning Systems

Air conditioning systems are widespread in industrial facilities, commercial buildings, and large institutions. The shift toward eco-friendly refrigerants is essential in ensuring energy efficiency and compliance with evolving regulations.

- CO2 (R-744): In air conditioning systems, especially in commercial refrigeration and HVAC applications, CO2 has emerged as a sustainable option due to its low GWP and good heat exchange properties.

- HFC-32 (R-32): In the HVAC sector, R-32 is increasingly used in air conditioning and heat pump systems due to its low GWP (675), making it a viable alternative to older refrigerants like R-410A.

Benefits:

- Reduced energy consumption due to the efficiency of eco-friendly refrigerants.

- Compliance with global regulations aimed at phasing out high-GWP refrigerants.

- Increased safety with refrigerants that have non-toxic and non-flammable properties.

4. Transport Refrigeration

Refrigerated transport is essential for maintaining the quality of perishable goods, including food, pharmaceuticals, and chemicals. The adoption of eco-friendly refrigerants is being seen in both land and maritime transport systems.

- CO2 (R-744) is increasingly used in refrigerated transport, such as trucks and shipping containers, due to its low GWP and safety.

- Hydrocarbons (R-290): Used in small vehicle refrigeration systems, hydrocarbons offer excellent energy efficiency and a GWP of just 3. These systems are already in use in small refrigerated vans and trucks.

Benefits:

- Sustainability by reducing emissions from refrigerants in the transport sector.

- Energy efficiency leading to reduced operating costs for transport fleets.

- Regulatory compliance, particularly with international shipping regulations.

5. Refrigeration in Data Centers

Data centers require significant cooling to ensure that servers and equipment maintain optimal operating temperatures. The cooling systems for these centers are being redesigned to use eco-friendly refrigerants to reduce their environmental impact.

- CO2 (R-744) and HFO-based refrigerants are being used in cooling systems for data centers to improve energy efficiency.

Benefits:

- Enhanced cooling performance that ensures operational efficiency.

- Reduction in carbon footprint, which helps businesses meet their sustainability goals.

Conclusion:

The industrial application of eco-friendly refrigerants is essential for addressing global climate change while maintaining efficiency and productivity. Industries such as food processing, chemical production, HVAC, transport refrigeration, and data centers are increasingly adopting natural and low-GWP refrigerants to reduce their environmental impact and comply with global regulations.

By investing in eco-friendly refrigerants, businesses can:

- Achieve cost savings through energy efficiency.

- Meet environmental regulations and avoid penalties.

- Enhance brand reputation as a sustainable and responsible entity.

This shift is not just about compliance; it is also about creating a sustainable future for the next generation. The widespread adoption of eco-friendly refrigerants will be crucial to mitigating climate change, improving air quality, and preserving natural resources.

Let me know if you’d like further details or need more specific examples of eco-friendly refrigerant applications!

Research and development of Eco-accommodating Refrigerants ?

Research and Development (R&D) of Eco-Friendly Refrigerants

The research and development (R&D) of eco-friendly refrigerants is a critical area in addressing the environmental impacts of cooling and refrigeration systems worldwide. Traditional refrigerants, such as CFCs, HCFCs, and HFCs, have high Global Warming Potential (GWP) and contribute significantly to climate change. As a result, there is growing interest in developing sustainable alternatives that have low GWP, zero Ozone Depletion Potential (ODP), and are non-toxic, non-flammable, and energy-efficient.

The ongoing R&D in the field of eco-friendly refrigerants focuses on several aspects, including the discovery of new refrigerants, the optimization of existing alternatives, improving energy efficiency, ensuring safety, and overcoming system compatibility challenges. This section outlines key areas of R&D in eco-friendly refrigerants and discusses the emerging trends and technologies that are shaping the future of refrigeration and cooling.

1. Natural Refrigerants

1.1 Carbon Dioxide (CO2, R-744)

CO2 (R-744) is one of the most promising natural refrigerants due to its zero ODP, low GWP, and environmental safety. Research has focused on improving transcritical CO2 systems, which are used in applications like supermarkets and industrial refrigeration. However, CO2 operates at high pressures, which can present technical challenges.

Key Areas of R&D for CO2:

- Efficiency improvements: Enhancing the energy efficiency of CO2-based systems through innovations in compressor technology, expansion valves, and heat exchangers.

- System design: Developing hybrid systems that combine CO2 with other refrigerants (like ammonia or HFCs) to improve performance in certain conditions (e.g., lower ambient temperatures).

- Reliability and durability: Researching better materials and system components to handle the high pressures of transcritical CO2 systems.

1.2 Ammonia (R-717)

Ammonia (R-717) is another natural refrigerant with zero GWP and is widely used in industrial refrigeration applications. Although it is highly efficient and cost-effective, ammonia is toxic and flammable, which poses safety concerns.

Key Areas of R&D for Ammonia:

- Safety enhancements: Developing safety technologies such as leak detection systems, containment measures, and advanced monitoring systems to reduce the risk associated with ammonia leaks.

- System optimization: Research to improve the energy efficiency of ammonia refrigeration systems, focusing on heat exchange, compressor technologies, and overall system design.

- Alternative applications: Expanding the use of ammonia in smaller-scale applications (e.g., transportation refrigeration and commercial systems) by improving system safety and reducing ammonia’s potential for harm.

1.3 Hydrocarbons (e.g., R-290, R-600a)

Hydrocarbons like propane (R-290) and isobutane (R-600a) are natural refrigerants that have low GWP and zero ODP. They are ideal for small-scale refrigeration systems, including household refrigerators, air conditioning units, and coolers.

Key Areas of R&D for Hydrocarbons:

- Flammability concerns: Research to develop safe, leak-proof systems and improved controls to mitigate flammability risks in hydrocarbon-based systems.

- Energy efficiency: Enhancing the thermodynamic performance of hydrocarbon refrigerants to improve energy efficiency, especially for household and small commercial refrigeration systems.

- Compatibility and standardization: Standardizing safety protocols for the widespread use of hydrocarbons in refrigeration, particularly in developing countries.

2. Low-GWP Synthetic Refrigerants

2.1 Hydrofluoroolefins (HFOs)

Hydrofluoroolefins (HFOs), such as R-1234yf and R-1234ze, are low-GWP refrigerants that are becoming increasingly important as alternatives to HFCs. HFOs have extremely low GWP (less than 1) and no ODP, making them suitable for automotive air conditioning, commercial refrigeration, and HVAC systems.

Key Areas of R&D for HFOs:

- Improved energy efficiency: Developing systems and technologies that maximize the thermodynamic performance of HFOs, improving their energy efficiency in different applications (e.g., automotive, HVAC, refrigeration).

- Blending HFOs: Researching blended refrigerants that combine HFOs with hydrofluorocarbons (HFCs) or hydrocarbons to optimize their energy performance, while ensuring low GWP and safe operation.

- Long-term environmental impact: Studying the long-term environmental effects of HFOs, particularly in terms of their atmospheric lifetime and potential degradation products.

2.2 HFC-32 (R-32)

HFC-32 (R-32) is a low-GWP refrigerant (GWP ~675) with a high energy efficiency, often used in HVAC systems and air conditioning. It has a lower GWP compared to many traditional refrigerants, such as R-410A (GWP ~2,088).

Key Areas of R&D for R-32:

- System optimization: Improving system performance in air conditioners, especially in high-ambient temperature environments. Research focuses on compressor efficiency, heat exchangers, and optimizing heat transfer.

- Safety considerations: Although R-32 is less flammable than other refrigerants, research continues into safety protocols, leak detection, and handling procedures.

- Long-term environmental performance: Ongoing evaluation of R-32’s impact on the environment over extended periods, particularly with respect to its global warming potential and chemical stability.

3. Alternative Technologies and Innovations

3.1 Magnetic Refrigeration

Magnetic refrigeration is a novel cooling technology that does not rely on traditional refrigerants. It uses the magnetocaloric effect, where materials heat up when exposed to a magnetic field and cool down when the field is removed.

Key Areas of R&D for Magnetic Refrigeration:

- Material discovery: Research into new magnetocaloric materials that provide better performance at higher temperatures for cooling systems.

- System development: Designing compact, energy-efficient systems that can operate in both consumer and industrial refrigeration applications.

- Commercialization: Overcoming technical challenges, such as cost, scalability, and efficiency, to make magnetic refrigeration a commercially viable alternative to conventional refrigerants.

3.2 Thermal Energy Storage and Heat Pumps

The development of thermal energy storage (TES) systems and heat pumps integrated with eco-friendly refrigerants is a promising area of research. These systems can store cooling or heating energy for use during peak demand, thereby improving energy efficiency and reducing electricity consumption.

Key Areas of R&D for TES and Heat Pumps:

- Hybrid systems: Combining eco-friendly refrigerants with thermal storage technologies to create energy-efficient solutions for heating and cooling.

- System design optimization: Improving thermal management techniques for better performance in diverse applications (e.g., district heating/cooling, residential systems).

4. Challenges in R&D of Eco-Friendly Refrigerants

- Safety Concerns: Many natural refrigerants, such as ammonia and hydrocarbons, are toxic or flammable, which requires ongoing research into safety systems, leak prevention, and risk management.

- Compatibility: Ensuring that new refrigerants are compatible with existing systems or designing new systems that can operate effectively with eco-friendly refrigerants remains a technical challenge.

- Cost: The development and implementation of new refrigerants can involve significant upfront costs, particularly in industries that need to retrofit existing systems.

- Infrastructure: In some cases, there is a lack of infrastructure for handling and distributing new refrigerants, requiring investment in training, standards, and system upgrades.

5. Conclusion

The research and development of eco-friendly refrigerants is a dynamic and crucial area for achieving sustainable cooling solutions in the face of global climate challenges. Advancements in natural refrigerants like CO2, ammonia, and hydrocarbons, along with low-GWP synthetic refrigerants such as HFOs and R-32, are driving the transition toward greener refrigeration systems.

As R&D efforts continue, the focus remains on improving energy efficiency, system safety, and environmental impact. The future of refrigeration will rely heavily on the successful development of these alternatives and the integration of innovative technologies such as magnetic refrigeration and thermal energy storage.

Let me know if you need any further details or specific research on any aspect of eco-friendly refrigerants!

COURTESY : Pramod Mathur

References

- ^ United Nations Environment Programme (UNEP). “Update on New Refrigerants Designations and Safety Classifications” (PDF). ASHRAE. Retrieved 6 October 2024.

- ^ “Phaseout of Class II Ozone-Depleting Substances”. US Environmental Protection Agency. 22 July 2015. Retrieved October 6, 2024.

- ^ “Protecting Our Climate by Reducing Use of HFCs”. United States Environmental Protection Agency. 8 February 2021. Retrieved 6 October 2024.

- ^ “refrigerant (CHEBI:78433)”. www.ebi.ac.uk. Retrieved 2025-02-22.

- ^ Li, Yalun; Yang, Jialiang; Wu, Xilei; Liu, Ying; Zhuang, Yuan; Zhou, Peixu; Han, Xiaohong; Chen, Guangming (2023-05-01). “Leakage, diffusion and distribution characteristics of refrigerant in a limited space:A comprehensive review”. Thermal Science and Engineering Progress. 40: 101731. doi:10.1016/j.tsep.2023.101731. ISSN 2451-9049.

- ^ Jump up to:a b Pearson, S. Forbes. “Refrigerants Past, Present and Future” (PDF). R744. Archived from the original (PDF) on 2018-07-13. Retrieved 2021-03-30.

- ^ Jump up to:a b c “Finally, a replacement for R123?”. Cooling Post. 17 October 2013.

- ^ https://asrjetsjournal.org/index.php/American_Scientific_Journal/article/download/3297/1244/

- ^ Jump up to:a b Tomczyk, John (1 May 2017). “What’s the Latest with R-404A?”. achrnews.com.

- ^ Molina, Mario J.; Rowland, F. S (28 June 1974). “Stratospheric sink for chlorofluoromethanes: chlorine catalysed destruction of ozone” (PDF). Nature. 249: 810–812. doi:10.1038/249810a0. Retrieved October 6, 2024.

- ^ National Research Council (1976). Halocarbons: Effects on Stratospheric Ozone. Washington, DC: The National Academies Press. doi:10.17226/19978. ISBN 978-0-309-02532-4. Retrieved October 6, 2024.

- ^ “Air Conditioners, Dehumidifiers, and R-410A Refrigerant”. Sylvane. 1 July 2011. Retrieved 27 July 2023.

- ^ Protection, United States Congress Senate Committee on Environment and Public Works Subcommittee on Environmental (May 14, 1987). “Clean Air Act Amendments of 1987: Hearings Before the Subcommittee on Environmental Protection of the Committee on Environment and Public Works, United States Senate, One Hundredth Congress, First Session, on S. 300, S. 321, S. 1351, and S. 1384 …” U.S. Government Printing Office – via Google Books.

- ^ Fluorinated Hydrocarbons—Advances in Research and Application (2013 ed.). ScholarlyEditions. June 21, 2013. p. 179. ISBN 9781481675703 – via Google Books.

- ^ Whitman, Bill; Johnson, Bill; Tomczyk, John; Silberstein, Eugene (February 25, 2008). Refrigeration and Air Conditioning Technology. Cengage Learning. p. 171. ISBN 978-1111803223 – via Google Books.

- ^ “Scroll Chillers: Conversion from HCFC-22 to HFC-410A and HFC-407C” (PDF). Archived from the original (PDF) on 2021-07-20. Retrieved 2021-03-29.

- ^ “What’s Happening With R-134a? | 2017-06-05 | ACHRNEWS | ACHR News”. achrnews.com.

- ^ “Conversion R12/R134a” (PDF). Behr Hella Service GmbH. 1 October 2005. Retrieved 27 July 2023.

- ^ “R-407A Gains SNAP OK”. achrnews.com (Press release). 22 June 2009.

- ^ “June 26, 2009: Emerson Approves R-407A, R-407C for Copeland Discus Compressors”. achrnews.com.

- ^ “Taking New Refrigerants to the Peak”. achrnews.com.

- ^ Koenig, H. (31 December 1995). “R502/R22 – replacement refrigerant R507 in commercial refrigeration; R502/R22 – Ersatzkaeltemittel R507 in der Gewerbekuehlung. Anwendungstechnik – Kaeltemittel”.

- ^ Linton, J. W.; Snelson, W. K.; Triebe, A. R.; Hearty, P. F. (31 December 1995). “System performance comparison of R-507 with R-502”. OSTI 211821.

- ^ “Daikin reveals details of R32 VRV air conditioner”. Cooling Post. 6 February 2020.

- ^ Jump up to:a b “Refrigerant blends to challenge hydrocarbon efficiencies”. Cooling Post. 22 December 2019.

- ^ “An HVAC Technician’s Guide to R-454B”. achrnews.com.

- ^ “The truth about new automotive A/C refrigerant R1234YF”. 25 July 2018.

- ^ Kontomaris, Konstantinos (2014). “HFO-1336mzz-Z: High Temperature Chemical Stability and Use as A Working Fluid in Organic Rankine Cycles”. International Refrigeration and Air Conditioning Conference.

Paper 1525

- ^ “Trane adopts new low GWP refrigerant R514A”. Cooling Post. 15 June 2016.

- ^ “R404A – the alternatives”. Cooling Post. 26 February 2014.

- ^ “Carrier expands R1234ze chiller range”. Cooling Post. 20 May 2020.

- ^ “Carrier confirms an HFO refrigerant future”. Cooling Post. 5 June 2019.

- ^ “Greenfreeze: A revolution in domestic refrigeration”. ecomall.com. Retrieved 2022-07-04.

- ^ Jump up to:a b “Happy birthday, Greenfreeze!”. Greenpeace. 25 March 2013. Archived from the original on 2020-04-08. Retrieved 8 June 2015.

- ^ “Ozone Secretariat”. United Nations Environment Programme. Archived from the original on 12 April 2015.

- ^ Gunkel, Christoph (13 September 2013). “Öko-Coup aus Ostdeutschland”. Der Spiegel (in German). Retrieved 4 September 2015.

- ^ Maté, John (2001). “Making a Difference: A Case Study of the Greenpeace Ozone Campaign”. Review of European Community & International Environmental Law. 10 (2): 190–198. doi:10.1111/1467-9388.00275.

- ^ Benedick, Richard Elliot Ozone Diplomacy Cambridge, MA: Harvard University 1991.

- ^ Honeywell International, Inc. (2010-07-09). “Comment on EPA Proposed Rule Office of Air and Radiation Proposed Significant New Alternatives Policy (SNAP) Protection of Stratospheric Ozone: Listing of Substitutes for Ozone-Depleting Substances – Hydrocarbon Refrigerants” (PDF).

- ^ “Discurso de Frank Guggenheim no lançamento do Greenfreeze | Brasil”. Greenpeace.org. Archived from the original on 24 September 2015. Retrieved 10 June 2015.

- ^ “Der Greenfreeze – endlich in den USA angekommen”. Greenpeace.de (in German). 28 December 2011. Retrieved 10 June 2015.

- ^ “Complying With The Section 608 Refrigerant Recycling Rule | Ozone Layer Protection – Regulatory Programs”. Epa.gov. 21 April 2015. Retrieved 10 June 2015.

- ^ Jump up to:a b “Greenfreeze: a Revolution in Domestic Refrigeration”. ecomall.com. Retrieved 8 June 2015.

- ^ “Company background”. Archived from the original on 2020-02-20. Retrieved 2021-03-15.

- ^ Safeguarding the ozone layer and the global climate System: issues related to Hydrofluorocarbons and Perfluorocarbons (Report). IPCC/TEAP. 2005.

- ^ Crowley, Thomas J. (2000). “Causes of Climate Change over the Past 1000 Years”. Science. 289 (5477): 270–277. Bibcode:2000Sci…289..270C. doi:10.1126/science.289.5477.270. PMID 10894770.

- ^ “2010 to 2015 government policy: environmental quality”. GOV.UK. 8 May 2015. Retrieved 10 June 2015.

- ^ “PepsiCo Brings First Climate-Friendly Vending Machines to the U.S.” phx.corporate-ir.net. Retrieved 8 June 2015.

- ^ “Climate-Friendly Greenfreezers Come to the United States”. WNBC. 2 October 2008. Retrieved 8 June 2015.

- ^ Data, Reports and (7 August 2020). “Natural Refrigerants Market To Reach USD 2.88 Billion By 2027 | Reports and Data”. GlobeNewswire News Room (Press release). Retrieved 17 December 2020.

- ^ Harris, Catharine. “Anti-inhalant Abuse Campaign Targets Building Codes: ‘Huffing’ of Air Conditioning Refrigerant a Dangerous Risk.” The Nation’s Health. American Public Health Association, 2010. Web. 5 December 2010. https://www.thenationshealth.org/content/39/4/20

- ^ IPCC AR6 WG1 Ch7 2021

- ^ “GreenFreeze”. Greenpeace.

- ^ “Significant New Alternatives Program: Substitutes in Household Refrigerators and Freezers”. Epa.gov. 13 November 2014. Retrieved 4 June 2018.

- ^ Berwald, Juli (29 April 2019). “One overlooked way to fight climate change? Dispose of old CFCs”. National Geographic – Environment. Archived from the original on April 29, 2019. Retrieved 30 April 2019.

- ^ Butler J. and Montzka S. (2020). “The NOAA Annual Greenhouse Gas Index (AGGI)”. NOAA Global Monitoring Laboratory/Earth System Research Laboratories.

- ^ Environment, U. N. (31 October 2019). “New guidelines for air conditioners and refrigerators set to tackle climate change”. UN Environment. Retrieved 30 March 2020.

- ^ Rosenthal, Elisabeth; Lehren, Andrew (20 June 2011). “Relief in Every Window, but Global Worry Too”. The New York Times. Retrieved 21 June 2012.

- ^ Jump up to:a b Yadav et al 2022

- ^ Jump up to:a b c BSRIA 2020

- ^ Jump up to:a b c d e f g h IPCC AR5 WG1 Ch8 2013, pp. 714, 731–737

- ^ “European Commission on retrofit refrigerants for stationary applications” (PDF). Archived from the original on August 5, 2009. Retrieved 2010-10-29.

- ^ “Protection of Stratospheric Ozone: Hydrocarbon Refrigerants” (PDF). Environment Protection Agency. Retrieved 5 August 2018.

- ^ ARB 2022

- ^ GM to Introduce HFO-1234yf AC Refrigerant in 2013 US Models

- ^ “The Coca-Cola Company Announces Adoption of HFC-Free Insulation in Refrigeration Units to Combat Global Warming”. The Coca-Cola Company. 5 June 2006. Archived from the original on 1 November 2013. Retrieved 11 October 2007.

- ^ “Modine reinforces its CO2 research efforts”. R744.com. 28 June 2007. Archived from the original on 10 February 2008.

- ^ Longo, Giovanni A.; Mancin, Simone; Righetti, Giulia; Zilio, Claudio (2015). “HFC32 vaporisation inside a Brazed Plate Heat Exchanger (BPHE): Experimental measurements and IR thermography analysis”. International Journal of Refrigeration. 57: 77–86. doi:10.1016/j.ijrefrig.2015.04.017.

- ^ May 2010 TEAP XXI/9 Task Force Report

- ^ “Protecting Our Climate by Reducing Use of HFCs”. US Environmental Protection Agency. 8 February 2021. Retrieved 25 August 2022.

- ^ “Background on HFCs and the AIM Act”. www.usepa.gov. US EPA. March 2021. Retrieved 27 June 2024.

- ^ “1:Update on Ozone-Depleting Substances (ODSs) and Other Gases of Interest to the Montreal Protocol”. Scientific assessment of ozone depletion: 2018 (PDF) (Global Ozone Research and Monitoring Project–Report No. 58 ed.). Geneva, Switzerland: World Meteorological Organization. 2018. p. 1.10. ISBN 978-1-7329317-1-8. Retrieved 22 November 2020.

- ^ [1] Chemours M099 as R22 Replacement

- ^ [2] Management of HCFC-123 through the Phaseout and Beyond | EPA | Published August 2020 | Retrieved Dec. 18, 2021

- ^ [3] Refrigerant R11 (R-11), Freon 11 (Freon R-11) Properties & Replacement

- ^ [4] R-454B XL41 refrigerant fact & info sheet

- ^ [5] R-454B emerges as a replacement for R-410A | ACHR News (Air Conditioning, Heating, Refrigeration News)

- ^ [6] Carrier introduces [R-454B] Puron Advance™ as the next generation refrigerant for ducted residential, light commercial products in North America | Indianapolis – 19 December 2018

- ^ [7] Johnson Controls selects R-454B as future refrigerant for new HVAC equipment | 27 May 2021

- ^ [8] A conversation on refrigerants | ASHRAE Journal, March 2021 | page 30, column 1, paragraph 2

- ^ [9] Opteon™ XP30 (R-514A) refrigerant

- ^ [10] Trane adopts new low GWP refrigerant R514A | 15 June 2016

- ^ “Emissions of Greenhouse Gases in the United States 1998 – Executive Summary”. 18 August 2000. Archived from the original on 18 August 2000.

- ^ “Frequently Asked Questions on Section 608”. Environment Protection Agency. Retrieved 20 December 2013.

- ^ “US hydrocarbons”. Retrieved 5 August 2018.

- ^ “42 U.S. Code § 7671g – National recycling and emission reduction program”. LII / Legal Information Institute.

- ^ ASHRAE; UNEP (Nov 2022). “Designation and Safety Classification of Refrigerants” (PDF). ASHRAE. Retrieved 1 July 2023.

- ^ “Update on New Refrigerants Designations and Safety Classifications” (PDF). American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). April 2020. Archived from the original (PDF) on February 13, 2023. Retrieved October 22, 2022.

Recommended HashTags

- #refrigerator

- #hvaclife

- #airconditioner

- #hvacservice

- #hvacr

- #heating

- #deepfreeze

- #bprefcool

- #refrigerantesfreezing

- #dairyfreeze

- #freezers

- #supermarketcabinet

- #supermarket

- #drinks

- #hvacrepair

- #supermarketcase

- #coolingsystems

- #electrical

- #refrigerationtech