Ventilation Plan Boundaries

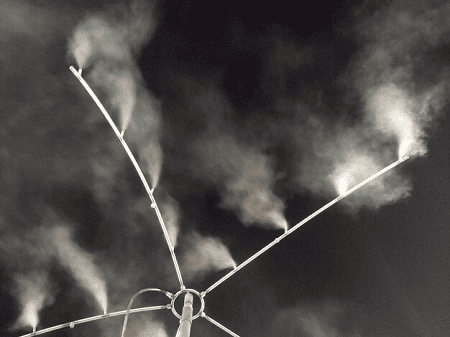

Ventilation Plan Boundaries ? When discussing “ventilation plan boundaries,” the context can vary significantly depending on the setting. Here’s a breakdown of key considerations: 1. Mining Ventilation: 2. Building Ventilation: Key Considerations: In essence, “ventilation plan boundaries” encompass both the physical limits of airflow and the documented parameters of a ventilation system. What is Ventilation Plan Boundaries ? The term “ventilation plan boundaries” refers to the defined limits and parameters of a ventilation system. This concept can vary depending on the context, primarily within mining and building applications. Here’s a breakdown: In Mining: In Building Ventilation: General Considerations: In summary, “ventilation plan boundaries” encompass the physical limits of airflow and the documented parameters of a ventilation system. Who is required Ventilation Plan Boundaries ? The requirement for ventilation plan boundaries applies to various entities, primarily those involved in: In essence, anyone responsible for spaces where inadequate ventilation could pose a health or safety risk is required to address ventilation plan boundaries. This responsibility is often defined by regulations and industry standards. When is required Ventilation Plan Boundaries ? The requirement for ventilation plan boundaries arises in several key situations, primarily centered around ensuring safety and health. Here’s a breakdown: 1. During Mine Development and Operation: 2. During Building Design and Construction: 3. In Industrial Settings: Key Triggers: In essence, ventilation plan boundaries are required whenever there’s a need to control and manage airflow to ensure safety, health, and regulatory compliance. COURTESY : HOME TUBE Where is required Ventilation Plan Boundaries ? Ventilation plan boundaries are required in a variety of settings, primarily where the control of airflow is essential for safety and health. Here’s a breakdown of the key locations: 1. Underground Mines: 2. Buildings: 3. Industrial Facilities: 4. Confined Spaces: In essence: Therefore, the “where” is very wide ranging, and driven by safety, health, and regulatory compliance. How is required Ventilation Plan Boundaries ? Creating and implementing adequate ventilation plan boundaries involves a multi-faceted approach, varying based on the specific environment (mining, building, industrial, etc.). Here’s a general overview of how it’s typically done: 1. Assessment and Planning: 2. Implementation: Key Considerations: In essence, “how” ventilation plan boundaries are required involves a systematic process of assessment, design, implementation, and ongoing maintenance, all guided by regulatory requirements and safety considerations. Case study is Ventilation Plan Boundaries ? When examining “Ventilation Plan Boundaries” through case studies, we find that the applications and challenges vary significantly across different sectors. Here’s a look at how this concept plays out in real-world scenarios: 1. Mining Ventilation Case Studies: 2. Building Ventilation Case Studies: 3. Industrial Ventilation Case Studies: General Case Study Considerations: By examining these case studies, we can gain valuable insights into the practical challenges and solutions associated with ventilation plan boundaries. COURTESY: Avinash Singh Kaushik White paper on Ventilation Plan Boundaries ? It’s important to understand that a “white paper” on “Ventilation Plan Boundaries” can take various forms, depending on the specific industry and focus. However, I can outline the key areas that would be covered in a comprehensive white paper, drawing from reliable sources: Key Areas for a Ventilation Plan Boundaries White Paper: Where to Find Relevant Information: By combining information from these sources, a comprehensive white paper on ventilation plan boundaries can be created. Industrial application of Ventilation Plan Boundaries ? Industrial applications of “Ventilation Plan Boundaries” are crucial for ensuring worker safety, environmental protection, and process efficiency. Here’s a breakdown of how these concepts are applied in industrial settings: Key Industrial Applications: Key Considerations: In essence, “Ventilation Plan Boundaries” in industrial applications are about creating and maintaining safe and healthy working environments by controlling the movement of air and contaminants. Research and development of Ventilation Plan Boundaries ? Research and development concerning “Ventilation Plan Boundaries” is a dynamic field, driven by the need to enhance safety, efficiency, and sustainability in various sectors. Here’s an overview of key R&D areas: 1. Computational Fluid Dynamics (CFD) Modeling: 2. Sensor Technology and Automation: 3. Air Filtration and Purification: 4. Mining Ventilation Research: 5. Building Ventilation and Indoor Air Quality: Key Drivers of R&D: By focusing on these areas, researchers are working to create more effective and sustainable ventilation systems that protect human health and the environment. COURTESY : Safety First References

Ventilation Plan Boundaries Read More »