Exhaust Systems ?

An exhaust system is a network of pipes and components that remove exhaust gases from an internal combustion engine or stove. Here’s a breakdown of its key functions and components:

Functions:

- Remove Exhaust Gases: Safely expel harmful gases produced during combustion away from the engine and passengers.

- Reduce Noise: Muffle the loud noises generated by the engine.

- Minimize Emissions: Treat exhaust gases to reduce pollutants released into the atmosphere.

Components:

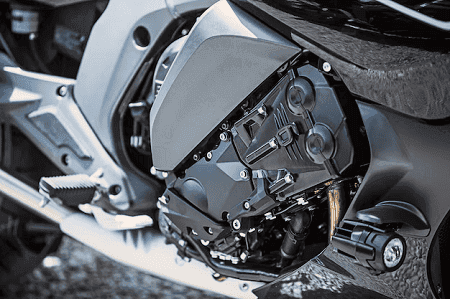

Exhaust Manifold: Collects exhaust gases from the engine cylinders. Exhaust Manifold

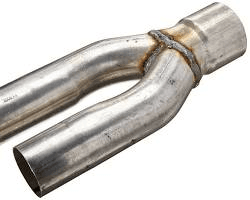

Catalytic Converter: Reduces harmful emissions by converting pollutants into less harmful substances. Catalytic Converter

Muffler: Dampens engine noise. Muffler

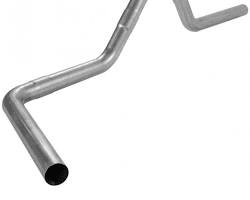

Pipes: Connect the various components and transport the exhaust gases. Exhaust Pipes

Tailpipe: The final section that releases the treated gases into the atmosphere. Tailpipe

Types of Exhaust Systems:

- Single Exhaust: One pipe exiting the vehicle.

- Dual Exhaust: Two pipes exiting the vehicle, often for performance or aesthetic reasons.

- Performance Exhaust: Designed for increased engine power and a sportier sound.

Maintenance:

- Regular Inspections: Check for leaks, damage, or loose components.

- Catalytic Converter Health: Ensure it’s functioning properly to minimize emissions.

- Muffler Condition: Replace if damaged or excessively noisy.

Additional Notes:

- Exhaust systems play a crucial role in vehicle emissions and noise control.

- Modifications to exhaust systems may affect vehicle performance, emissions, and legality.

- Some vehicles may have additional components like resonators or particulate filters to further reduce noise and emissions.

hat is Exhaust Systems ?

An exhaust system is like the respiratory system of your car. It’s a series of pipes and components that work together to:

- Remove harmful gases: Just like your lungs remove carbon dioxide, the exhaust system removes toxic gases produced by the engine, like carbon monoxide and nitrogen oxides.

- Reduce noise: Imagine your car without a muffler – it would be incredibly loud! The exhaust system includes a muffler to dampen the engine’s noise.

- Minimize pollution: Modern exhaust systems have catalytic converters that help clean up the exhaust gases before they’re released into the atmosphere, reducing pollution.

Think of it like this:

- Exhaust Manifold: This is where the journey begins. It collects the exhaust gases from the engine’s cylinders, like the trachea in your respiratory system.

- Catalytic Converter: This is the cleaning station. It uses chemical reactions to convert harmful pollutants into less harmful substances, like the alveoli in your lungs.

- Muffler: This is the silencer. It reduces the noise created by the engine, like your vocal cords controlling the sound of your voice.

- Pipes: These are the pathways. They transport the exhaust gases from the engine to the tailpipe, like the bronchi and bronchioles in your lungs.

- Tailpipe: This is the exit point. It releases the treated exhaust gases into the atmosphere, like your nose and mouth.

Why is it important?

A well-functioning exhaust system is crucial for:

- Your health: It keeps harmful gases away from you and your passengers.

- The environment: It reduces pollution and helps protect the air we breathe.

- Your car’s performance: It ensures the engine runs efficiently and smoothly.

Types of Exhaust Systems:

There are different types of exhaust systems, including:

- Single exhaust: One pipe exiting the vehicle.

- Dual exhaust: Two pipes exiting the vehicle, often for performance or aesthetic reasons.

- Performance exhaust: Designed for increased engine power and a sportier sound.

Taking care of your exhaust system:

Like any other part of your car, the exhaust system needs some attention. Regular inspections can help identify leaks, damage, or loose components. Keeping an eye on the catalytic converter and muffler is also important for optimal performance and emissions control.

Who is required Exhaust Systems ?

Exhaust systems are required for a wide range of vehicles and machines that use internal combustion engines. Here’s a breakdown of who needs them and why:

1. On-road vehicles:

- Cars: All cars, from the smallest hatchback to the largest SUV, require exhaust systems to manage emissions, noise, and safety.

- Trucks: Trucks, both light and heavy-duty, rely on exhaust systems to handle the powerful engines they use, ensuring efficient operation and compliance with regulations.

- Motorcycles: Motorcycles need exhaust systems to direct exhaust gases away from the rider, reduce noise, and often play a role in the bike’s performance and aesthetics.

- Buses: Buses, whether for public transport or private use, require exhaust systems to manage emissions and noise, especially in urban environments.

2. Off-road vehicles:

- Construction equipment: Bulldozers, excavators, and other construction machinery use exhaust systems to handle the demands of their powerful engines and ensure safe operation in demanding conditions.

- Agricultural vehicles: Tractors and other farm equipment need exhaust systems to manage emissions and noise in rural settings.

- ATVs and UTVs: All-terrain vehicles and utility task vehicles require exhaust systems for safety and to manage noise, especially in recreational areas.

3. Other machines:

- Generators: Generators, whether portable or stationary, use internal combustion engines and therefore need exhaust systems to manage emissions and noise.

- Industrial equipment: Many industrial machines, such as pumps and compressors, may be powered by internal combustion engines and require exhaust systems.

- Marine vessels: Boats and ships with inboard engines need exhaust systems to direct exhaust gases away from passengers and crew, reduce noise, and manage emissions in marine environments.

Why are exhaust systems required?

- Safety: Exhaust gases contain harmful substances like carbon monoxide, which can be fatal. Exhaust systems safely direct these gases away from people.

- Emissions: Modern exhaust systems, especially with catalytic converters, play a crucial role in reducing harmful emissions and protecting the environment.

- Noise control: Internal combustion engines are loud. Exhaust systems, particularly mufflers, significantly reduce noise pollution.

- Performance: In some cases, exhaust systems are designed to optimize engine performance by managing exhaust flow.

Regulations:

In most countries, there are strict regulations regarding vehicle emissions and noise levels. These regulations mandate the use of exhaust systems and often specify performance standards to ensure environmental protection and public safety.

In summary:

Exhaust systems are essential for any machine that uses an internal combustion engine. They are crucial for safety, environmental protection, noise control, and sometimes even performance. Due to their importance, they are subject to regulations in most parts of the world.

When is required Exhaust Systems ?

You need an exhaust system whenever you’re dealing with an internal combustion engine, whether it’s in a vehicle, a machine, or a generator. Here’s a breakdown of the key situations where an exhaust system is absolutely required:

1. When an engine is running:

- Every single time: As soon as an internal combustion engine starts, it produces exhaust gases that need to be safely managed. This means an exhaust system is necessary for every instance of engine operation, from the moment you turn on your car to the continuous running of a generator.

2. For all types of internal combustion engines:

- Gasoline and diesel: Whether your engine runs on gasoline or diesel, it produces harmful exhaust gases that necessitate an exhaust system.

- Two-stroke and four-stroke: Both types of engines, commonly found in motorcycles, lawnmowers, and some small engines, require exhaust systems to manage emissions and noise.

3. In various applications:

- Vehicles: Cars, trucks, motorcycles, buses, and any other on-road vehicle must have a properly functioning exhaust system to meet safety and emissions standards.

- Off-road equipment: Construction machinery, agricultural vehicles, ATVs, and other off-road machines with engines require exhaust systems for safe and efficient operation.

- Stationary engines: Generators, industrial equipment, and any engine that powers a stationary machine needs an exhaust system to manage emissions and noise.

4. To meet regulations:

- Emissions standards: Governments worldwide have strict regulations on vehicle emissions. Exhaust systems, especially with catalytic converters, are essential for meeting these standards.

- Noise control: Noise pollution is a concern, and exhaust systems, particularly mufflers, are crucial for reducing the noise produced by engines.

5. For safety and health:

- Toxic gases: Exhaust gases contain harmful substances like carbon monoxide, which can be fatal. Exhaust systems safely direct these gases away from people.

- Health concerns: Exposure to exhaust fumes can cause various health problems. A well-functioning exhaust system minimizes this risk.

In summary:

You need an exhaust system whenever an internal combustion engine is running. It’s not a matter of choice but a necessity for safety, environmental protection, noise control, and compliance with regulations.

Think of it this way:

Imagine a factory producing smoke and fumes. It needs a chimney to safely direct those substances away from the workers and the surrounding environment. An exhaust system is like the chimney for an engine, ensuring that harmful gases are managed responsibly.

COURTESY : Engineering Explained

Where is required Exhaust Systems ?

Exhaust systems are required in a wide variety of places where internal combustion engines are used. Here’s a breakdown of the key areas:

1. On public roads:

- Everywhere: Virtually every country in the world mandates exhaust systems for vehicles driven on public roads. This includes cars, trucks, motorcycles, buses, and any other vehicle designed for street use.

- Urban and rural areas: Whether you’re driving in a busy city or a quiet countryside, your vehicle needs a functioning exhaust system to comply with regulations and ensure safety.

2. Off-road environments:

- Designated areas: Even in off-road settings like national parks, forests, or private land, vehicles like ATVs, UTVs, and dirt bikes typically require exhaust systems to manage noise and emissions, especially in areas with environmental sensitivities.

- Work sites: Construction sites, farms, and other work areas where machinery operates often have regulations regarding exhaust systems to protect workers and the environment.

3. Industrial and commercial settings:

- Factories and plants: Industrial equipment powered by engines, such as generators, pumps, and compressors, needs exhaust systems to manage emissions and noise within the facility.

- Construction sites: Heavy machinery like excavators, bulldozers, and cranes require exhaust systems to ensure safe and compliant operation.

- Marine environments: Boats and ships with inboard engines need exhaust systems to direct exhaust gases away from passengers and crew, reduce noise, and manage emissions in the water.

4. Residential areas:

- Homes with generators: If you have a generator at home, it needs an exhaust system to minimize noise and emissions, especially if it’s used frequently or for extended periods.

- Properties with machinery: Even on private property, if you operate machinery with an engine, like a lawnmower or a chainsaw, it will have an exhaust system to manage noise and emissions.

5. Anywhere with regulations:

- Specific locations: Some areas, like near schools, hospitals, or residential zones, may have stricter noise regulations, requiring specific types of exhaust systems or additional noise reduction measures.

- Countries and regions: Different countries and regions have varying emissions and noise standards, which influence the requirements for exhaust systems.

In summary:

Exhaust systems are required wherever internal combustion engines are used, with regulations often varying depending on the location, type of vehicle or machinery, and specific environmental or noise concerns.

Think of it like this:

Just like a responsible factory needs a proper chimney to manage its emissions, any place where an engine operates requires an exhaust system to ensure safety, environmental protection, and compliance with regulations.

How is required Exhaust Systems ?

Exhaust systems are required for internal combustion engines due to a combination of factors related to safety, environmental protection, noise control, and performance. Here’s a breakdown of how these factors necessitate the use of exhaust systems:

1. Safety:

- Toxic gases: Internal combustion engines produce harmful gases like carbon monoxide, nitrogen oxides, and hydrocarbons. Carbon monoxide is odorless and can be fatal in even small concentrations. An exhaust system safely directs these gases away from the engine and passengers, preventing them from entering the cabin or causing harm.

- Fire hazard: Exhaust gases are hot and can ignite flammable materials. The exhaust system contains and channels these hot gases, reducing the risk of fires.

2. Environmental protection:

- Pollution: Exhaust gases contain pollutants that contribute to air pollution and can harm the environment. Modern exhaust systems, especially with catalytic converters, help reduce these pollutants by converting them into less harmful substances before they are released into the atmosphere.

- Regulations: Governments worldwide have strict regulations on vehicle emissions to protect the environment and public health. Exhaust systems are essential for meeting these regulations.

3. Noise control:

- Engine noise: Internal combustion engines are inherently noisy. The combustion process creates loud explosions that need to be muffled. The exhaust system, particularly the muffler, is designed to reduce this noise to acceptable levels, preventing noise pollution and making vehicles more comfortable to use.

- Regulations: Many areas have noise regulations to protect people from excessive noise pollution. Exhaust systems help vehicles comply with these regulations.

4. Performance:

- Exhaust flow: The design of the exhaust system can affect engine performance. A well-designed system can optimize exhaust flow, reducing backpressure and improving engine efficiency. This can lead to increased power output and better fuel economy.

- Tuning: In some cases, exhaust systems are modified or tuned to enhance engine performance, especially in high-performance vehicles.

In summary:

Exhaust systems are required because they play a crucial role in:

- Protecting people from harmful gases and fire hazards.

- Reducing pollution and protecting the environment.

- Controlling engine noise and preventing noise pollution.

- Optimizing engine performance.

Therefore, exhaust systems are not just an optional accessory but a necessary component for any internal combustion engine to ensure safety, environmental responsibility, noise control, and sometimes even performance enhancement.

Case study is Exhaust Systems ?

Let’s explore a case study focusing on exhaust systems, specifically looking at the evolution of catalytic converters and their impact on reducing vehicle emissions.

Case Study: The Evolution of Catalytic Converters

Background:

Before catalytic converters became widespread, vehicle exhaust emissions were a significant source of air pollution, contributing to smog, acid rain, and respiratory problems. The primary pollutants of concern were:

- Hydrocarbons (HC): Unburned fuel, contributing to smog.

- Carbon Monoxide (CO): A toxic gas produced by incomplete combustion.

- Nitrogen Oxides (NOx): Contribute to smog and acid rain.

Problem:

Growing awareness of the health and environmental impacts of these pollutants led to increasing pressure on automakers to reduce emissions. The challenge was to find a cost-effective and reliable way to significantly reduce the levels of these harmful substances in vehicle exhaust.

Solution:

The catalytic converter emerged as the most effective solution. It’s a device placed in the exhaust system that uses chemical reactions to convert harmful pollutants into less harmful substances:

- HC and CO are oxidized into carbon dioxide (CO2) and water (H2O).

- NOx is reduced into nitrogen (N2) and oxygen (O2).

Early catalytic converters were relatively simple, but they have evolved significantly over time. Key advancements include:

- Improved catalyst materials: Initially, platinum was the primary catalyst, but it’s expensive. Modern converters use a combination of platinum, palladium, and rhodium, which are more efficient and cost-effective.

- Three-way catalysts: These advanced converters can simultaneously reduce all three major pollutants (HC, CO, and NOx), making them highly effective.

- Improved design and manufacturing: Modern converters are designed for durability, efficiency, and to minimize backpressure on the engine.

Results:

The widespread adoption of catalytic converters has had a dramatic impact on air quality. Studies have shown significant reductions in HC, CO, and NOx emissions from vehicles. This has led to:

- Improved air quality in urban areas: Reduced smog and other forms of pollution.

- Reduced acid rain: Lower NOx emissions contribute to less acidic precipitation.

- Improved public health: Fewer respiratory problems linked to air pollution.

Challenges and Future Directions:

While catalytic converters have been highly successful, challenges remain:

- Cold start emissions: Converters are less effective when the engine is cold. Research is ongoing to improve their performance during cold starts.

- Durability and lifespan: Converters can degrade over time, reducing their effectiveness. Improving their durability is an ongoing focus.

- Cost: While the cost of catalytic converters has come down, they still add to the overall cost of a vehicle.

- Emerging technologies: With the rise of electric vehicles and other alternative fuel technologies, the future role of catalytic converters may change. However, they will likely continue to play a crucial role for vehicles with internal combustion engines for many years to come.

Conclusion:

The catalytic converter is a prime example of how technological innovation can address environmental challenges. Its widespread adoption has significantly reduced vehicle emissions and improved air quality. This case study highlights the importance of continued research and development to further improve exhaust system technology and address the ongoing challenges of air pollution.

COURTESY : How a Car Works

White paper on Exhaust Systems ?

White Paper: The Critical Role of Exhaust Systems in Modern Vehicles

Abstract:

Exhaust systems are more than just pipes that expel fumes; they are complex, integrated systems crucial for vehicle safety, environmental protection, noise control, and even performance. This white paper examines the evolution, function, importance, and future of exhaust systems in the context of modern vehicles, addressing key challenges and opportunities.

1. Introduction:

The internal combustion engine (ICE) has been the dominant power source for vehicles for over a century. While offering performance and practicality, ICEs produce harmful emissions and noise as byproducts. The exhaust system plays a critical role in mitigating these negative impacts. This paper explores the multifaceted role of exhaust systems, from their basic function to their increasing sophistication in response to stricter environmental regulations and evolving vehicle technologies.

2. Functions of an Exhaust System:

- Exhaust Gas Removal: The primary function is to safely channel exhaust gases away from the engine and occupants, preventing exposure to toxic substances like carbon monoxide.

- Emissions Control: Modern exhaust systems, equipped with catalytic converters and other components, significantly reduce harmful pollutants such as hydrocarbons (HC), carbon monoxide (CO), nitrogen oxides (NOx), and particulate matter (PM).

- Noise Reduction: Mufflers and resonators within the exhaust system dampen engine noise, contributing to a quieter and more comfortable driving experience.

- Performance Enhancement: In some applications, particularly performance vehicles, exhaust system design is optimized to improve engine efficiency and power output by minimizing backpressure.

3. Key Components of an Exhaust System:

- Exhaust Manifold: Collects exhaust gases from the engine cylinders.

- Catalytic Converter: Uses chemical reactions to convert harmful pollutants into less harmful substances. Three-way catalysts are the most common type, simultaneously reducing HC, CO, and NOx.

- Muffler: Dampens engine noise through a series of chambers and baffles.

- Resonator: Further reduces noise and can be used to tune the exhaust note.

- Pipes: Connect the various components and transport the exhaust gases.

- Oxygen Sensors: Monitor the oxygen content in the exhaust stream, providing feedback for engine management systems to optimize combustion and emissions control.

- Particulate Filters (Diesel Engines): Trap particulate matter from diesel exhaust.

4. Evolution of Exhaust Systems:

Early exhaust systems were primarily focused on directing fumes away from the vehicle. However, with growing environmental awareness and stricter regulations, exhaust systems have become increasingly sophisticated. Key milestones include:

- Introduction of Catalytic Converters: A major breakthrough in emissions control, significantly reducing harmful pollutants.

- Development of Three-Way Catalysts: Enabled simultaneous reduction of multiple pollutants.

- Advanced Muffler and Resonator Technology: Improved noise reduction and exhaust tuning capabilities.

- Diesel Particulate Filters: Addressed the specific challenge of particulate matter emissions from diesel engines.

5. Challenges and Future Directions:

- Cold Start Emissions: Catalytic converters are less effective when the engine is cold. Research is focused on improving cold start performance.

- Durability and Longevity: Exhaust system components can degrade over time due to heat, corrosion, and mechanical stress. Improving durability is an ongoing challenge.

- Lightweighting: Reducing the weight of exhaust systems can contribute to improved fuel efficiency.

- Integration with Alternative Fuel Technologies: Exhaust systems will need to adapt to the rise of hybrid, electric, and other alternative fuel vehicles. While electric vehicles don’t have traditional exhaust systems, the manufacturing process and lifecycle of these vehicles still have environmental considerations.

- Real-World Emissions Testing: Moving beyond laboratory testing to ensure that vehicles meet emissions standards in real-world driving conditions.

6. Conclusion:

Exhaust systems are essential components of modern vehicles, playing a critical role in safety, environmental protection, noise control, and sometimes even performance. As environmental regulations become stricter and vehicle technologies evolve, exhaust systems will continue to adapt and innovate. Focus areas include improving cold start performance, enhancing durability, reducing weight, and integrating with alternative fuel technologies. The future of exhaust systems will be shaped by the ongoing need to balance performance, environmental responsibility, and cost-effectiveness.

Industrial application of Exhaust Systems ?

Industrial exhaust systems are crucial for maintaining safe and healthy working environments, controlling pollution, and ensuring efficient operation of various industrial processes. Here are some key industrial applications of exhaust systems:

1. Manufacturing and Processing:

- Fume extraction: Many manufacturing processes generate harmful fumes, gases, and dust particles. Exhaust systems with specialized hoods and ductwork capture these contaminants at the source, preventing them from spreading throughout the facility and protecting workers’ health. Examples include welding fumes, chemical vapors, and dust from grinding or cutting operations.

- Process ventilation: Some industrial processes require precise control of air quality and temperature. Exhaust systems help maintain these conditions by removing excess heat, humidity, or unwanted gases. This is crucial in industries like pharmaceuticals, electronics manufacturing, and food processing.

- Dust collection: Industries that handle dry materials, such as woodworking, mining, and grain processing, generate large amounts of dust. Exhaust systems with dust collectors capture and remove this dust, preventing it from accumulating on surfaces, clogging machinery, and posing a health hazard.

2. Power Generation:

- Flue gas treatment: Power plants, especially those using fossil fuels, produce large volumes of flue gas containing pollutants. Exhaust systems in these facilities include equipment like scrubbers, electrostatic precipitators, and catalytic converters to remove pollutants before the gases are released into the atmosphere.

- Engine exhaust: Industrial generators and other equipment powered by internal combustion engines require exhaust systems to manage emissions and noise, similar to vehicles.

3. Laboratories and Research Facilities:

- Fume hoods: Laboratories use fume hoods to contain and exhaust hazardous chemicals and vapors, protecting researchers from exposure. These hoods are connected to dedicated exhaust systems that ensure proper ventilation and prevent the spread of contaminants.

- Cleanrooms: Some research and manufacturing processes require extremely clean air. Exhaust systems in cleanrooms help maintain this environment by removing particles and other contaminants that could affect sensitive experiments or products.

4. Waste Treatment and Recycling:

- Odor control: Waste treatment facilities and recycling plants often generate unpleasant odors. Exhaust systems can be used to capture and treat these odors, reducing their impact on the surrounding environment.

- Emissions control: Incinerators and other waste processing equipment require exhaust systems with pollution control devices to minimize the release of harmful substances into the air.

5. Other Industrial Applications:

- Mining: Underground mines require extensive ventilation systems to supply fresh air and remove harmful gases, dust, and heat.

- Agriculture: Large-scale livestock operations can produce significant amounts of ammonia and other gases. Exhaust systems can help manage these emissions and improve air quality in and around the facilities.

- Marine: Ships and other vessels with internal combustion engines need exhaust systems to manage emissions and noise, especially in sensitive marine environments.

Key Considerations for Industrial Exhaust Systems:

- Type of contaminant: The specific pollutants being generated will determine the type of exhaust system and any necessary treatment equipment.

- Airflow requirements: The volume of air that needs to be exhausted will influence the size and design of the system.

- Regulations: Industrial facilities must comply with various environmental and safety regulations regarding emissions and workplace air quality.

- Energy efficiency: Modern exhaust systems are designed to minimize energy consumption while still providing effective ventilation and pollution control.

- Maintenance: Regular maintenance is essential to ensure the proper functioning and longevity of industrial exhaust systems.

By effectively managing exhaust gases and contaminants, industrial exhaust systems play a vital role in protecting workers’ health, preserving the environment, and ensuring the smooth operation of various industrial processes.

Research and development of Exhaust Systems ?

Research and development (R&D) in exhaust systems is a dynamic field driven by increasingly stringent emissions regulations, the need for improved fuel efficiency, and the ongoing quest for enhanced vehicle performance. Here are some key areas of focus:

1. Advanced Emissions Control:

- Improving Catalytic Converter Efficiency: Research is focused on developing more efficient catalytic converters that can further reduce harmful pollutants, especially during cold starts when converters are less effective. This includes exploring new catalyst materials, optimizing converter design, and integrating them with other emissions control technologies.

- Reducing Particulate Matter Emissions: Diesel engines, and increasingly gasoline engines, face challenges in controlling particulate matter (PM) emissions. R&D efforts are directed towards improving diesel particulate filters (DPFs) and developing gasoline particulate filters (GPFs) with higher efficiency and durability.

- Controlling NOx Emissions: Nitrogen oxides (NOx) are a major contributor to smog. Research is ongoing to develop more effective NOx reduction technologies, such as selective catalytic reduction (SCR) systems and lean NOx traps (LNTs), for both diesel and gasoline engines.

2. Enhancing Fuel Efficiency:

- Reducing Backpressure: Exhaust system design can significantly impact engine performance and fuel efficiency. R&D efforts are focused on minimizing backpressure, the resistance to exhaust flow, to improve engine breathing and reduce fuel consumption.

- Optimizing Exhaust Flow: Computational fluid dynamics (CFD) simulations are used to optimize exhaust system design for improved flow characteristics, leading to better engine performance and fuel economy.

- Lightweighting: Reducing the weight of exhaust systems can contribute to overall vehicle weight reduction and improved fuel efficiency. This involves exploring new materials and manufacturing techniques.

3. Improving Noise Control:

- Active Noise Cancellation: R&D is exploring active noise cancellation technologies that use sound waves to counteract engine noise, offering the potential for more effective noise reduction compared to traditional mufflers.

- Tuning Exhaust Note: Some manufacturers are focusing on developing exhaust systems that can be tuned to produce a desired exhaust note, enhancing the driving experience while still meeting noise regulations.

4. Integrating with Alternative Fuel Technologies:

- Hybrid and Electric Vehicles: While electric vehicles don’t have traditional exhaust systems, R&D is focused on the environmental impact of their production and lifecycle. This includes looking at the materials used in batteries and other components, as well as the energy sources used in manufacturing.

- Fuel Cell Vehicles: Fuel cell vehicles produce water as a byproduct, but R&D is needed to manage this water and ensure the safe and efficient operation of the fuel cell system.

5. Advanced Materials and Manufacturing:

- High-Temperature Materials: Exhaust systems operate under extreme temperatures. R&D is exploring new materials, such as advanced alloys and ceramics, that can withstand these conditions and improve durability.

- Additive Manufacturing: 3D printing, or additive manufacturing, is being explored to create more complex and optimized exhaust system designs, potentially leading to improved performance and reduced weight.

6. Sensor Integration and Control:

- Smart Exhaust Systems: Integrating sensors and control systems into exhaust systems can enable real-time monitoring of emissions and performance, allowing for optimization and potential early detection of issues.

- Predictive Maintenance: Data from sensors can be used to predict potential failures and schedule maintenance proactively, reducing downtime and costs.

7. Regulatory Compliance and Testing:

- Real-World Emissions Testing: R&D is focused on developing exhaust systems that meet increasingly stringent emissions standards, not just in laboratory tests but also in real-world driving conditions.

- Durability and Longevity: Ensuring that exhaust systems maintain their performance and meet emissions standards over the lifespan of the vehicle is a key area of research.

Collaboration and Innovation:

R&D in exhaust systems often involves collaboration between automakers, suppliers, research institutions, and government agencies. This collaborative approach fosters innovation and helps accelerate the development of cleaner, more efficient, and higher-performing exhaust systems for the future.

COURTESY : Custom Offsets

References

- ^ How Headers Work How Headers Improve Engine Performance

- ^ “Exhaust Science Demystified”. superchevy.com. 16 May 2005. Retrieved 31 August 2019.

- ^ “Environmental Protection Agency” (PDF). US Government Printing Office. Retrieved 17 March 2017.

- ^ Under federal law, catalytic converters may not be removed and replaced with “converter replacement pipes” by any person. The Clean Air Act of 1990 prohibits private individuals from installing “converter replacement pipes” on their vehicles. Anyone who installs such pipes would violate section 203(a)(3)(A) and (B) of the Clean Air Act (Act). In addition to federal law, forty-five of the fifty States have statutes or regulations prohibiting tampering with pollution control equipment on motor vehicles or driving or selling such vehicles. Thus, vehicle owners who tamper with their vehicles may be subject to substantial penalties under federal and state law.

- ^ “Fact Sheet: Exhaust System Repair Guidelines” (PDF). United States Environmental Protection Agency. 13 March 1991. Retrieved 17 March 2017.

- ^ Volkmann, Jörg (2007). “2”. Exhaust systems’ models investigation by theoretical group methods. Göttingen Cuvillier. pp. 13–34. ISBN 9783867274227. Retrieved 17 March 2017.

- ^ Fernández-Yáñez, P.; Armas, O.; Gómez, A.; Gil, A. (2017-06-08). “Developing Computational Fluid Dynamics (CFD) Models to Evaluate Available Energy in Exhaust Systems of Diesel Light-Duty Vehicles”. Applied Sciences. 7 (6): 590. doi:10.3390/app7060590.

- ^ “What you should know about using, installing or buying aftermarket catalytic converters” (PDF). epa.gov. Archived from the original (PDF) on 14 April 2014.

- ^ “The Power of 2.5- vs. 3-Inch Exhaust – Engine Masters Ep. 9”. youtube.com. MotorTrend Channel. Archived from the original on 2021-12-13. Retrieved 9 September 2019.

- ^ “Exhaust Performance and Scavenging”. autolounge.net. Archived from the original on 12 August 2011.

- ^ “How Mufflers Work – Inside a Muffler”. howstuffworks.com. 19 February 2001. Retrieved 31 August 2019.

- ^ “The truth about exhaust backpressure and torque”. uucmotorwerks.com. Archived from the original on 1 July 2012. Retrieved 16 May 2012.

- ^ “Backpressure: Friend or Foe?” (PDF). veryuseful.com. Retrieved 31 August 2019.

- ^ “Your Car’s Warranty”. scuderiasystems.com. Archived from the original on 22 February 2015.

- ^ Ohsasa, Y.; Kadomatsu, K. (1995). “Sound Quality Evaluation of Exhaust Note During Acceleration”. SAE Transactions. 104: 2324–2331. ISSN 0096-736X. JSTOR 44729295.

- The Design and Tuning of Competition Engines, Philip H. Smith, pp137-138

- ^ “What does a 4-2-1 exhaust system do?”. www.howstuffworks.com. 21 December 2011. Retrieved 24 September 2019.

- ^ “4-1 vs 4-2-1 Headers – What is the difference? What makes more power?”. www.redline360.com. 19 October 2012. Retrieved 24 September 2019.

- ^ “Header Dyno Testing & Comparison, Tri Y vs. 4 Into 1”. www.superstreetonline.com. Retrieved 24 September 2019.

- ^ Jump up to:a b “Exhaust System Technology: Science and Implementation of High Performance Exhaust Systems”. www.epi-eng.com. Retrieved 25 October 2019.

- ^ “Firing Order Swaps”. www.enginelabs.com. Retrieved 25 October 2019.

- ^ “Bill Sherwood’s Engine Page – Exhaust”. www.billzilla.org. Retrieved 24 September 2019.